Your Singer sewing machine might look like a simple box with a needle, but inside it’s a masterpiece of precision engineering. Every time you press that foot pedal, you’re commanding an intricate dance of motors, gears, and levers that transforms thread into perfect stitches faster than any human hand could manage. Understanding how this mechanical marvel works isn’t just fascinating—it’ll help you troubleshoot problems, maintain your machine better, and even improve your sewing technique.

Let’s pull back the curtain on what’s really happening beneath that smooth exterior and discover the ingenious mechanisms that make modern sewing possible. When you know how a Singer sewing machine works, you’ll gain confidence in your sewing projects and develop the ability to diagnose issues before they ruin your fabric.

Electric Motor Powers All Stitching Operations

The electric motor sits at the heart of your Singer, typically tucked inside the main column near where you plug in the power cord. This motor doesn’t just make the needle go up and down—it orchestrates three separate mechanisms that must work in perfect synchronization.

Your motor drives a pulley system that connects to the large handwheel at the machine’s right side. This handwheel, which you can turn manually for slow, precise stitching, serves as the main power distributor. Through a series of belts and gears, it splits power between the needle mechanism, the bobbin shuttle, and the feed dogs.

How Motor Power Distributes to Critical Components

The motor’s power gets divided like this:

– Primary shaft drives the needle up and down through a crankshaft mechanism

– Secondary gearing rotates the shuttle twice per needle cycle for proper stitch formation

– Tertiary mechanism controls the feed dog’s complex elliptical movement pattern

When you press the foot pedal, you’re controlling the motor’s speed, which directly affects how quickly these three mechanisms work together. The motor’s torque must be strong enough to push the needle through multiple fabric layers while maintaining perfect timing between all moving parts.

Needle Mechanism Creates Precise Up-and-Down Motion

The needle mechanism converts the motor’s rotary motion into the exact vertical movement required for consistent stitching. A crankshaft attached to the main drive wheel pushes the needle bar in a perfectly controlled path—this isn’t random bouncing but an engineered motion calibrated to create uniform stitches.

Here’s what happens during each needle cycle:

1. Downward stroke: Needle pierces fabric at exact center point

2. Lowest position: Creates a precise thread loop beneath the fabric

3. Upward stroke: Leaves the loop for the shuttle hook to catch

4. Return position: Resets for the next stitch formation cycle

Why Needle Timing Matters for Perfect Stitches

The needle’s eye sits just above the sharp point, positioned to deliver the top thread exactly where it’s needed. Unlike hand sewing, the needle never pulls thread all the way through—it only pushes the thread down, creating loops that get locked with the bobbin thread below. If the needle timing drifts even slightly, your stitches will become inconsistent or skip entirely.

Bobbin and Shuttle Create the Lock Stitch Magic

The real magic happens beneath your fabric where you can’t see it. The bobbin—a small spool holding your bottom thread—sits inside a rotating shuttle that spins twice for every complete needle cycle. This precise 2:1 ratio is crucial for creating the lock stitch that holds your seams together.

Thread tension systems on both top and bottom threads ensure each stitch pulls tight without breaking. Too loose, and your seams unravel. Too tight, and your fabric puckers or threads break. The shuttle’s hook catches the needle thread loop at the exact moment the needle begins its upward journey, pulling the needle thread completely around the bobbin thread to create a secure lock.

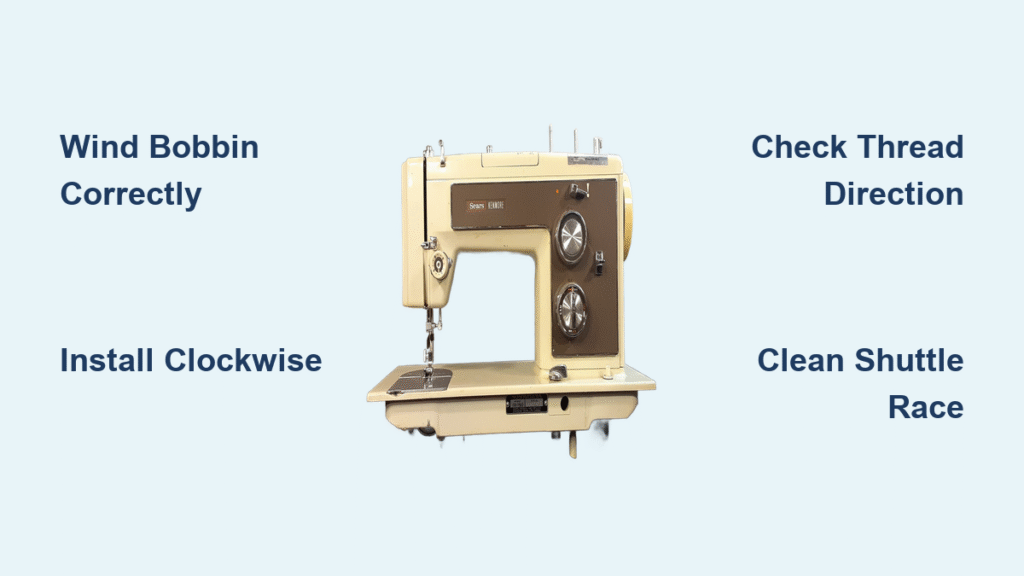

Troubleshooting Common Bobbin Issues

When your Singer creates “bird nests” of tangled thread underneath your fabric, it’s usually because:

– Bobbin thread tension is too loose

– The bobbin isn’t seated correctly in the shuttle

– You’ve threaded the machine incorrectly

– Lint has accumulated in the bobbin area

Cleaning the bobbin area after every project prevents 80% of these frustrating issues.

Feed Dog Mechanism Advances Fabric Precisely

The feed dog mechanism represents pure mechanical genius. This small, toothed metal plate beneath the presser foot doesn’t just move up and down—it performs a precise elliptical motion that grips your fabric and advances it exactly one stitch length at a time.

Two separate mechanisms create this movement:

– Vertical motion: Raises teeth to grip fabric against presser foot

– Horizontal motion: Pulls fabric forward by precise stitch length

– Perfect synchronization: Coordinates with needle timing to prevent fabric movement during needle penetration

Why Your Fabric Might Not Feed Properly

If your Singer’s feed dogs aren’t moving fabric correctly, check these common problem areas:

– Lint and thread fragments clogging the feed dog teeth

– Presser foot pressure set too low for thick fabrics

– Feed dog height adjustment needing calibration

– Worn feed dog teeth from years of use on heavy materials

Regular cleaning with a small brush prevents most feed dog problems and keeps your stitches perfectly even.

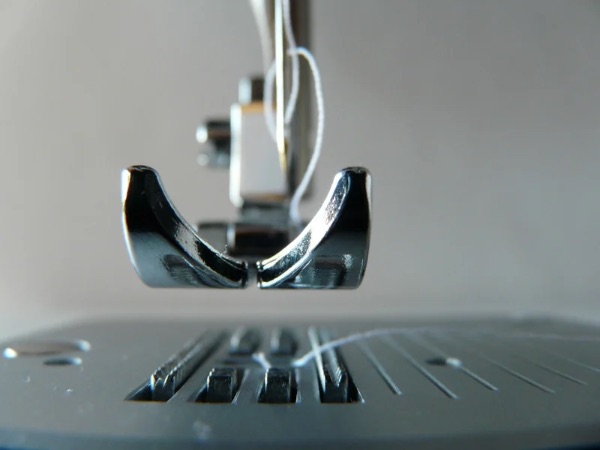

Lock Stitch Formation: Six-Step Precision Process

Your Singer creates each stitch through a precisely timed six-step process that repeats hundreds of times per minute:

Step 1: Needle descends with top thread, piercing fabric at exact center point

Step 2: Needle reaches lowest point, creating a thread loop beneath fabric

Step 3: Shuttle hook catches the needle thread loop at the perfect moment

Step 4: Shuttle rotates, pulling needle thread completely around bobbin thread

Step 5: Needle rises, pulling thread to tighten the stitch formation

Step 6: Both threads lock in center of fabric, completing one perfect stitch

This entire cycle happens so fast—up to 1,000 times per minute—that you’d never notice the complex interaction without slowing it down. The precision engineering ensures every stitch locks securely without tangling.

Essential Singer Controls and What They Actually Do

Your Singer’s exterior controls directly influence these internal mechanisms:

Thread Tension Dial: Adjusts pressure on top thread, affecting stitch tightness—too loose causes unraveling, too tight causes puckering

Stitch Length Lever: Changes feed dog travel distance, controlling how far fabric advances with each stitch

Stitch Selector: On electronic models, chooses different cam patterns for decorative stitches

Presser Foot Lever: Raises/lowers presser foot to engage/disengage feed dogs

Handwheel: Manual control for precise needle positioning during pivots or delicate work

Pro Tip for Better Stitch Quality

When working with slippery fabrics like silk or satin, slightly increase your presser foot pressure and reduce stitch length. This gives the feed dogs better grip while preventing the fabric from shifting during needle penetration.

Diagnosing Common Singer Machine Problems

When your Singer malfunctions, these mechanical relationships provide diagnostic clues:

Skipped stitches: Usually indicates timing issues between needle and shuttle hook—often caused by a bent needle or improper needle installation

Bird nesting underneath: Bobbin thread tension too loose or threading error—check both top and bottom threading paths

Fabric not advancing: Feed dog obstruction or insufficient presser foot pressure for fabric thickness

Breaking needles: Needle hitting shuttle hook due to timing drift or using wrong needle size for fabric weight

Uneven stitches: Feed dog teeth worn or fabric not feeding smoothly—clean feed dogs and check for obstructions

Most problems stem from these core mechanisms getting out of sync. Regular cleaning, proper threading, and correct needle installation prevent 90% of common issues.

Maintenance That Keeps Your Singer Running Smoothly

Your Singer’s mechanical precision requires regular maintenance to function properly:

After every project: Remove lint from feed dogs and bobbin area using the small brush included with your machine

Weekly: Apply one drop of sewing machine oil to designated points (check your manual—modern machines need less oil than vintage models)

Monthly: Check for loose screws, replace worn needles, and clean thread paths

Annually: Professional service for timing adjustment and deep cleaning—especially important for vintage Singer machines

Critical Warning: Oil Selection Matters

Never use household oils like 3-in-1 or WD-40 on your Singer sewing machine. These oils gum up over time and attract lint. Always use proper sewing machine oil designed for precision mechanisms.

Modern Singer Innovations Building on Classic Mechanics

While Singer’s core mechanical principles remain unchanged, modern machines add electronic control:

Computerized stitch selection: Microprocessors control multiple cam positions for hundreds of decorative stitches

Automatic tension: Sensors adjust thread pressure based on fabric thickness detected by the machine

Speed control: Electronic regulation maintains consistent stitching speed regardless of fabric resistance

Needle positioning: Precise stop positioning for pivoting and applique work without manual handwheel adjustment

These additions enhance the core mechanical systems without replacing them. Your electronic Singer still relies on the same needle, shuttle, and feed dog mechanisms developed over 170 years ago—proof of their brilliant engineering.

Why Understanding Your Singer Makes You a Better Sewist

Knowing how a Singer sewing machine works transforms you from a button-pusher into a skilled operator who can:

– Diagnose problems before they ruin your projects

– Adjust settings precisely for different fabrics

– Maintain equipment to extend its lifespan

– Troubleshoot issues without professional help

– Achieve consistently professional results

The next time you press that foot pedal, you’ll appreciate the engineering marvel humming beneath your fingertips. Every stitch represents centuries of mechanical innovation packed into a compact machine that makes possible the creative fashion and textile arts we enjoy today. When you understand how your Singer works, you’re not just operating a machine—you’re participating in a rich tradition of mechanical ingenuity that continues to evolve while honoring its fundamental principles.