Your Singer sewing machine was stitching smoothly an hour ago—now it’s leaving gaping holes in your quilt seam. Those skipped stitches aren’t just annoying; they’ll unravel your project the moment someone tugs the fabric. Whether you’re hemming maternity jeans or stitching silk dupioni, missing stitches mean weak seams and wasted hours.

Here’s the truth: 95% of skipped stitch problems stem from six fixable issues you can solve in under 10 minutes. No special tools needed—just your machine, a fresh needle, and this battle-tested guide. Follow these exact steps to eliminate gaps and sew with confidence again.

Replace Your Singer Needle Before Anything Else

A bent or worn needle causes more skipped stitches than any other issue. Even a hairline bend invisible to the naked eye will deflect when hitting fabric, missing the bobbin hook entirely.

Why Your Current Needle is the Culprit

Roll your removed needle on glass. If it wobbles—even slightly—it’s bent. Inspect for:

– Dull tips (feels blunt when lightly scratched on fingernail)

– Burrs inside the eye (catches thread when pulled through)

– Shaft curvature (visible when comparing to new needle)

Pro Tip: Change needles every 6-8 sewing hours. That “one project” rule? It’s outdated. Heavy denim or sequined fabric shreds needles in just 2 hours.

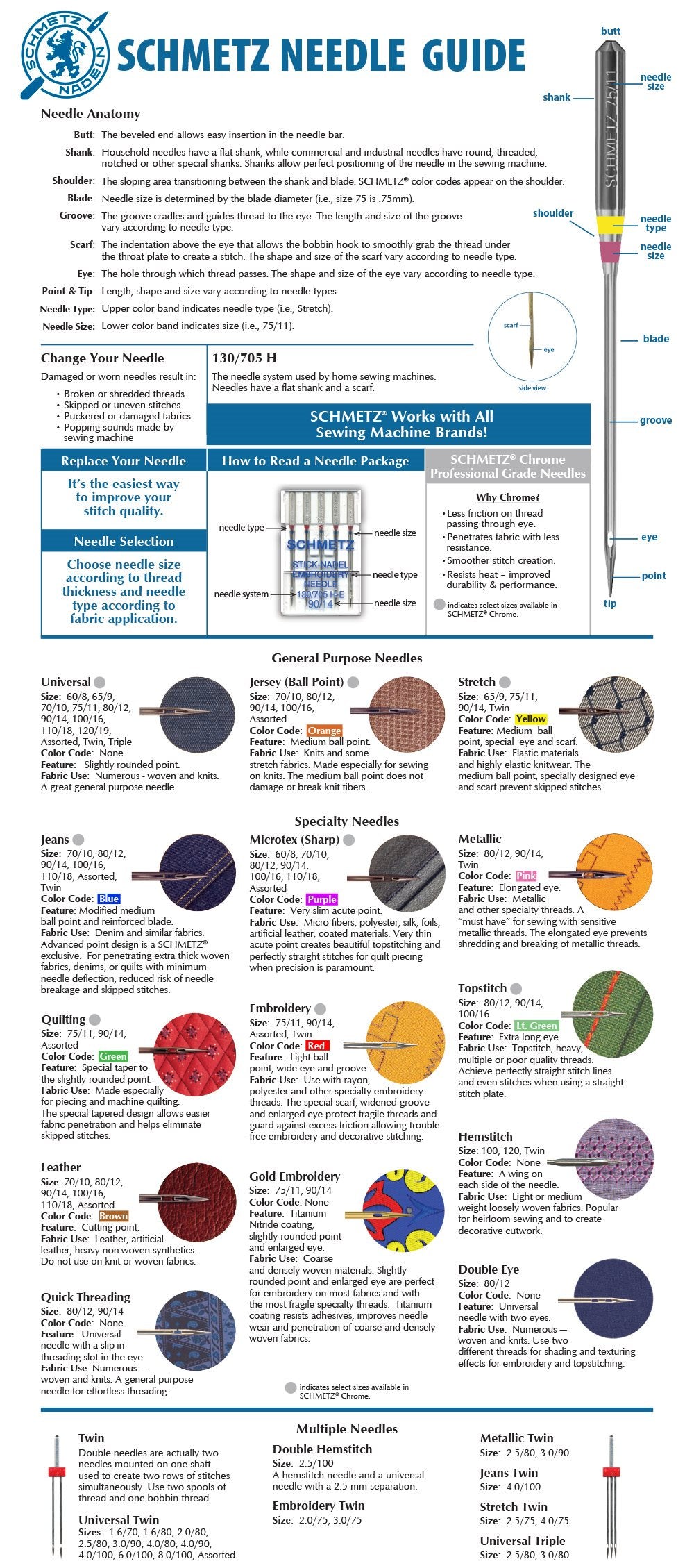

Match Needle Type to Fabric Exactly

Using a universal needle on knits guarantees skipped stitches. Switch based on fabric:

| Fabric Type | Needle Size | Needle Type | Critical Reason |

|---|---|---|---|

| Silk, chiffon | 60/8-70/10 | Microtex | Pierces without shredding fibers |

| Cotton, linen | 80/12-90/14 | Universal | Balanced penetration for wovens |

| Jersey, spandex | 70/10-80/12 | Stretch | Deep scarf prevents loop skipping |

| Denim, canvas | 100/16-110/18 | Denim | Reinforced shaft pierces thick layers |

Warning: Ballpoint needles on wovens will skip stitches. The rounded tip pushes threads aside instead of piercing cleanly.

Install the Needle Perfectly

70% of “needle issues” are actually installation errors. Verify:

1. Flat shank faces backward (toward machine body on Singer models)

2. Needle pushed all the way up until it hits the stop

3. Clamp screw tightened firmly—loose needles wobble at high speed

Re-thread Your Singer Machine Like a Pro

Threading mistakes cause 40% of skipped stitches. Even experienced sewists miss the take-up lever slot—and that single error ruins every stitch.

The 60-Second Re-threading Protocol

Follow this sequence exactly:

1. Raise presser foot (releases tension discs)

2. Turn handwheel clockwise until needle is at highest position

3. Check spool cap fit—wobbling spools cause uneven thread feed

4. Thread path sequence: Spool → first guide → tension discs → take-up lever slot → needle bar guide → needle eye

5. Pull 6 inches of thread tail toward machine back before sewing

Critical Check: Thread must sit inside the take-up lever’s metal slot—not behind it. Run your finger along the lever; if thread catches, it’s misrouted.

Ditch Cheap Thread Immediately

Bargain-bin thread sheds fibers that clog Singer tension discs. Use:

– Gutermann Mara 100 (polyester) for 95% of projects

– Aurifil Mako for fine cottons and quilting

– Never use decades-old thread—UV exposure makes it brittle

Match thread weight to needle size: Heavy 40-wt thread needs a 100/16 needle minimum. Lightweight 60-wt thread on a 90/14 needle = skipped stitches.

Fix Singer Tension in 3 Adjustments

Tension imbalances mimic needle problems but fix in minutes. Skip this step and you’ll chase ghosts.

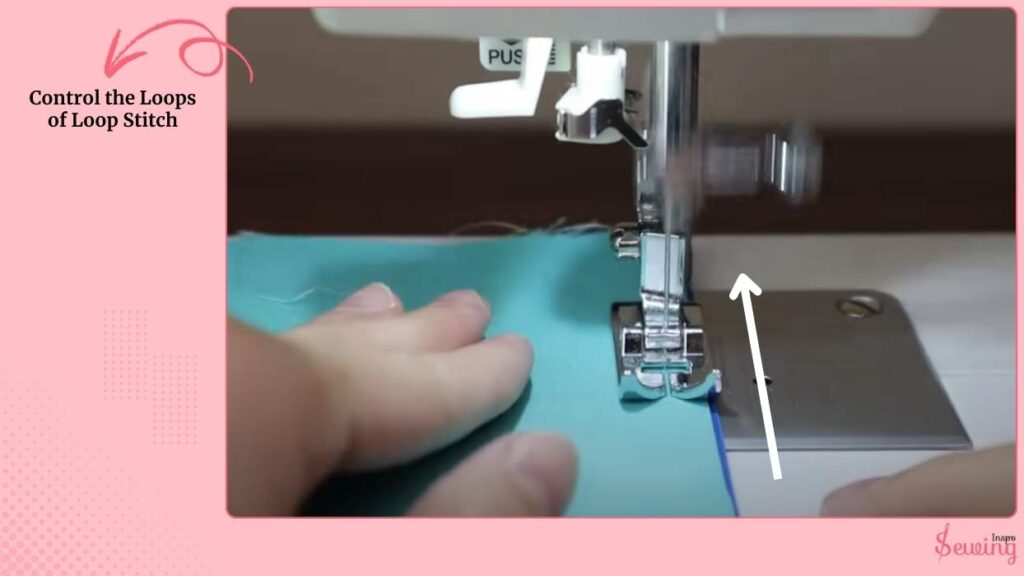

The 4-Inch Tension Test That Works

Sew on doubled scrap fabric matching your project:

– Loops UNDER fabric → Top tension too loose (turn dial higher)

– Bobbin thread showing ON TOP → Top tension too tight (turn dial lower)

Adjust in 0.5 increments. Most Singer machines stitch perfectly between 3.5–4.5. Heavy denim may need 5.5, silk as low as 2.5.

Red Flag: If tension dial is at 2 or 8 with no improvement, revisit needle/thread pairing before assuming machine damage.

Clean Your Singer Bobbin System Properly

Lint buildup causes random skipped stitches that seem “intermittent.” Canned air makes this worse by packing debris deeper.

Bobbin Installation Fail-Safes

- Drop-in models (Simple, Heavy Duty): Pull thread—bobbin must rotate counter-clockwise

- Front-load models (15-class): Listen for the click when inserting bobbin case

The 90-Second Cleaning Method

- Remove needle plate (loosen thumb screws)

- Brush hook race and bobbin area with dry paintbrush (no oil yet)

- Check bobbin winding—even tension from top to bottom

- Add one drop of sewing machine oil only if manual specifies

Never skip: Lint trapped under feed dogs causes stitches to skip every 5-7 stitches. Brush teeth thoroughly.

Check Feed Dogs and Presser Foot Pressure

Misaligned feed dogs or incorrect pressure cause skipped stitches on thick seams—especially in quilting.

Feed Dog Emergency Check

- Raised position: Drop-feed lever pushed right (most Singers)

- Clear teeth: Remove lint with tweezers—never use needles (scratches metal)

- Bent teeth: Professional repair needed if any tooth is visibly damaged

Presser Foot Pressure Fixes

- Light fabrics: Reduce pressure to prevent fabric puckering

- Denim/leather: Increase pressure using dial on machine top

- Slippery fabrics: Use Teflon foot—regular feet stick and skip stitches

Pro Tip: Walking feet eliminate skipped stitches on quilt sandwiches. The dual-feed mechanism grips top and bottom layers.

Fabric-Specific Skipped Stitch Solutions

Generic advice fails on specialty fabrics. Match these exact fixes:

Stop Skipped Stitches on Knits

- Needle: Stretch 75/11

- Thread: Wooly nylon in bobbin + polyester top thread

- Stitch: Use lightning-stitch (stretch straight stitch) if available

Fix Skipped Stitches on Denim

- Needle: Denim 100/16 with new point (blunt tips deflect)

- Stitch length: 3.0–3.5mm (shorter stitches won’t penetrate)

- Presser foot: Jeans foot with deep throat clearance

Rescue Silk and Satin Projects

- Needle: Microtex 60/8

- Stitch plate: Use straight-stitch plate to prevent fabric drop-down

- Speed: Sew slowly—high speed causes needle deflection on delicate fabrics

The 8-Step Skipped Stitch Emergency Kit

When stitches keep skipping, run this diagnostic in order:

1. Install new needle—correct size/type for fabric

2. Re-thread top AND bobbin—follow path diagram

3. Adjust tension—test on scrap after each tweak

4. Clean bobbin area—remove all lint

5. Test on scrap—same fabric as project

6. Swap fabric—try quilting cotton to isolate issue

7. Check feed dogs/pressure—raised? Unobstructed?

8. Professional help—if skips persist after step 7

When to Call a Singer Repair Tech

Stop troubleshooting if you see:

– Needle hitting bobbin case (metallic ping sound)

– Stitches skipping every 3rd-4th stitch (timing issue)

– No improvement after all 8 steps

Cost Reality Check: Professional servicing ($80–$120) costs less than replacing a vintage Singer 500+ machine. Machines over 8 years old need timing checks every 2 years—neglect causes chronic skipped stitches.

Your skipped stitch prevention checklist:

– [ ] Needle changed before project start

– [ ] Take-up lever threaded through slot

– [ ] Thread weight matches needle size

– [ ] Tension tested on project fabric scrap

– [ ] Bobbin rotates freely in correct direction

– [ ] Feed dogs raised and lint-free

– [ ] Presser foot pressure adjusted for fabric weight

– [ ] Test seam sewn at project speed

With these fixes, your Singer will sew flawless stitches from delicate voile to triple-layer canvas. No more unraveling seams or wasted fabric—just confident, professional results on every project. Grab that needle package now and stitch with certainty.