Your Kenmore sewing machine worked flawlessly yesterday, but today the bobbin thread is tangling in a bird’s nest under the fabric, the case keeps popping out mid-seam, or the hook won’t catch the upper thread at all. These exact frustrations plague Kenmore owners daily—whether you’re wrestling with a vintage 158-16801 or a Janome-built 385.16231. The critical truth? 90% of Kenmore bobbin thread issues stem from three fixable causes you can resolve in under 30 minutes with basic tools. This guide delivers the precise diagnostic steps professional technicians use for Kenmore’s horizontal drop-in bobbin systems, cutting through guesswork to get you stitching again.

Stop wasting time with trial-and-error fixes. You’ll learn to identify the exact culprit by observing thread behavior, apply model-specific solutions that work on the first try, and implement prevention habits that stop these problems from recurring. Every solution here targets the unique mechanics of your Kenmore machine.

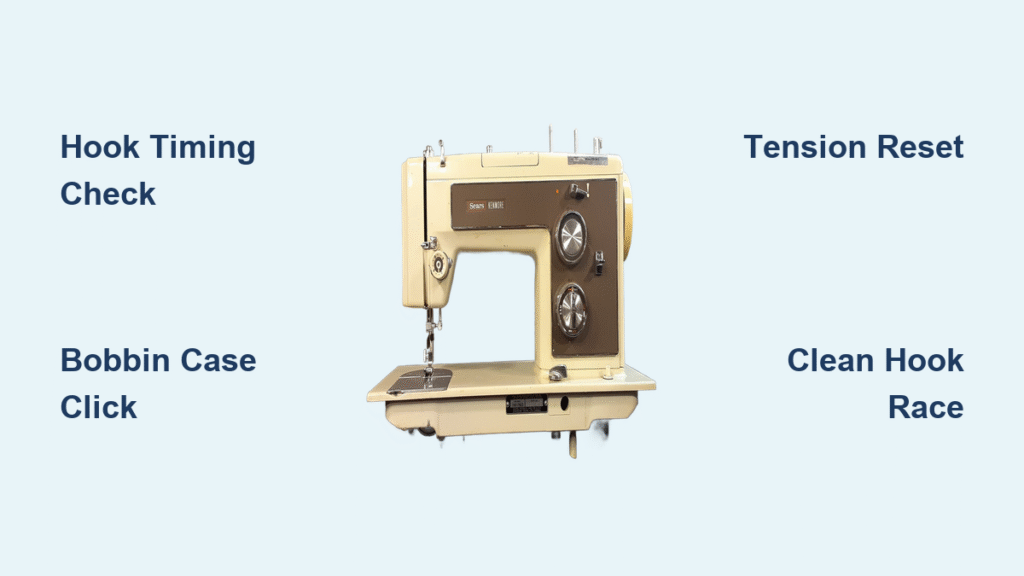

Hook Won’t Catch Upper Thread on Kenmore Machines

When your needle plunges but returns without bringing up the bobbin thread, the timing between needle and hook has shifted. This commonly hits mechanical models like the 158-16801 after hitting thick fabric layers or during transport. Don’t assume it’s broken—this is often a simple alignment issue.

Verify Needle-to-Hook Alignment First

Remove the needle plate and bobbin case. Install a fresh needle with the flat side facing the hook tip. Slowly turn the hand wheel toward you until the needle reaches its lowest point. As the needle starts rising, the hook tip must pass directly behind the needle’s scarf (the curved groove above the eye).

Critical visual checks:

– Hook tip misses the scarf entirely → timing severely misaligned

– Hook strikes needle → bent needle or major timing error

– Hook passes too high/low → minor timing adjustment needed

If you spot misalignment, proceed immediately to the fix below—continuing to sew will worsen the problem.

Quick Timing Fix for 158-16801 Models

- Remove the right side base cover (two screws)

- Locate the round shaft with two set screws (not under the needle bar)

- Loosen screws ¼ turn with a small flat screwdriver

- Hold needle at lowest point; rotate hand wheel to position hook tip 1-2mm above needle eye

- Retighten screws evenly while maintaining position

- Test by hand-wheeling through 10 stitches without fabric

Pro tip: Clamp a clothespin against the shaft as a temporary wedge to prevent lateral drift while tightening screws. Test with contrasting thread colors to clearly see if the hook catches the upper thread loop consistently.

Bobbin Case Pops Out Mid-Sewing on Kenmore Models

When your bobbin case works loose during sewing—especially on 385.16231 machines—the latch mechanism isn’t securing properly. This often happens when sewing heavy fabrics like denim, causing sudden tension collapse and thread nests. Forcing the case back in without fixing the root cause risks damaging your hook assembly.

Secure Case Installation Steps

- Power off and raise needle to highest position

- Remove needle plate completely

- Clean hook race area thoroughly with brush and tweezers

- Check spring clip tension—press outward on the case side; it should spring back firmly

- Listen for the distinct click when inserting case—must snap under retainer ring

- Tighten needle plate screws firmly—loose plates allow micro-shifts that dislodge cases

Critical mistake to avoid: Never hammer a stubborn case into place. This bends the spring clip and creates burrs that snag thread.

Spring Clip Inspection Guide

| Spring Condition | Immediate Fix |

|---|---|

| Bent outward | Gently bend back to 45-degree angle using needle-nose pliers |

| Cracked or broken | Replace entire bobbin case immediately |

| Weak tension | Replace spring clip or entire case assembly |

Warning: Forcing a bent spring clip back into position guarantees repeated failure and may damage the hook race. If the spring won’t hold tension after bending, replacement is mandatory.

Thread Nests Under Fabric on Kenmore Sewing Machines

Heavy looping or bunching underneath your fabric indicates tension imbalance—this is the #1 issue reported for 385.16231300 models. Don’t waste time adjusting dials blindly; follow this systematic reset protocol targeting Kenmore’s specific tension path vulnerabilities.

Top Tension Reset Protocol

- Unthread completely—remove spool and pull thread back through all guides

- Raise presser foot to fully open tension discs

- Clean discs by running a folded fabric scrap through the path 5 times

- Use compressed air in 2-second bursts to remove hidden “dust bunnies”

- Rethread carefully—ensure thread passes through every guide and take-up lever eyelet

- Test tension—pull thread with foot down; should feel medium resistance

Visual cue: If thread slips through your fingers when pulled with foot down, tension discs are contaminated or misaligned.

Bobbin Tension Quick Test

Hold the bobbin case by the latch. The thread should unwind with steady, gentle pressure. If it:

– Won’t unwind → loosen bobbin tension screw ⅛ turn counterclockwise

– Falls out freely → tighten screw ⅛ turn clockwise

– Varies while pulling → re-wind bobbin evenly (Kenmore drop-in systems require perfect winding)

Pro insight: Uneven bobbin winding causes intermittent tension spikes that mimic mechanical failure—always check this before disassembling your machine.

Clean Kenmore Hook Assembly in 5 Minutes

Lint buildup disrupts the precise 0.5mm clearance needed between hook and needle. This single cleaning step prevents 90% of recurring bobbin thread issues on all Kenmore models.

Complete Cleaning Sequence

- Remove needle plate (store screws in magnetic tray)

- Take out bobbin and case

- Brush hook race with stiff nylon brush—focus on corners where lint traps

- Tweeze stubborn lint from feed dog teeth

- Apply one drop of sewing machine oil to metal hub only (never on plastic)

- Reinstall case until distinct click heard

- Test with hand wheel before powering on

Expert note: Clean after every 8-10 sewing hours or immediately after fleece/velvet. Mechanical Kenmores tolerate less lint than computerized models before failing.

Prevent Thick Fabric Damage on Kenmore Sewing Machines

Needle deflection during heavy sewing throws off timing—common when stitching bra straps or denim hems. The needle bends left, strikes the hook, and causes immediate bobbin thread issues.

Bulk Management Techniques

- Hammer thick seams flat with a rubber mallet before sewing

- Use a Jean-a-ma-jig (or plastic needle case under presser foot back)

- Lengthen stitch to 3.5-4.0mm for thick areas

- Slow hand-wheel over high spots with needle down to pivot

- Switch to size 90/14 needle for denim layers

Critical tip: Never force fabric—this pulls threads out of tension. Let the feed dogs advance fabric at their natural pace.

Replace Worn Kenmore Bobbin Parts Correctly

When cleaning and adjustment fail, these specific parts commonly need replacement. Using incorrect parts causes recurring bobbin thread problems.

Essential Kenmore Part Numbers

| Part | Compatible Models | Correct Replacement |

|---|---|---|

| Bobbin case | 385.16231, 385.16231300, 18221 | Janome 796804110 |

| Needles | All horizontal bobbin models | System 15×1 / HAx1 |

| Bobbins | All horizontal models | Class 15 clear plastic |

Compatibility check: New bobbin cases must have two alignment arrows and a metal spring clip on the side. Never substitute vertical bobbin parts.

Quick Symptom Fix Matrix for Kenmore Machines

Bookmark this rapid-reference guide for instant troubleshooting:

| Problem | First Fix | If Still Broken |

|---|---|---|

| Hook won’t pick up thread | Verify needle direction (flat side toward hook) | Check timing alignment |

| Case pops out mid-seam | Clean race and reseat with firm click | Inspect spring clip tension |

| Thread bunching below fabric | Reset top tension path | Check bobbin tension screw |

Long-Term Kenmore Reliability Tips

Ensure decades of trouble-free sewing with these model-specific habits:

– Wind bobbins evenly—Kenmore drop-in systems fail with uneven wind

– Clean in place instead of frequent case removal (reduces misalignment)

– Zero tension dials monthly to prevent lint lock-up

– Use high-quality thread—cheap thread sheds lint that jams Kenmore tension discs

– Store covered to keep dust out of bobbin area

Pro insight: Vintage mechanical Kenmores like the 158-16801 respond better to DIY repairs than computerized models. Master these techniques, and bobbin thread issues become rare interruptions rather than daily frustrations. The horizontal drop-in system rewards proper technique with decades of reliable stitching—once you know exactly what to check when problems strike.