Your Juki sewing machine thread keeps breaking every few stitches, leaving you with tangled nests, snapped threads, and ruined fabric. That familiar ping as the thread snaps mid-seam isn’t just annoying—it wastes precious time and materials while derailing your creative flow. Whether you’re working on a delicate bridal gown or heavy upholstery, persistent thread breakage on Juki machines usually stems from preventable issues hiding in plain sight.

The good news? Over 90% of Juki thread breaking problems resolve with simple adjustments you can make in under 15 minutes. This guide cuts through the confusion with model-specific solutions verified by professional technicians. You’ll discover exactly why your thread snaps and how to fix it—no guesswork required—so you can return to sewing smoothly today.

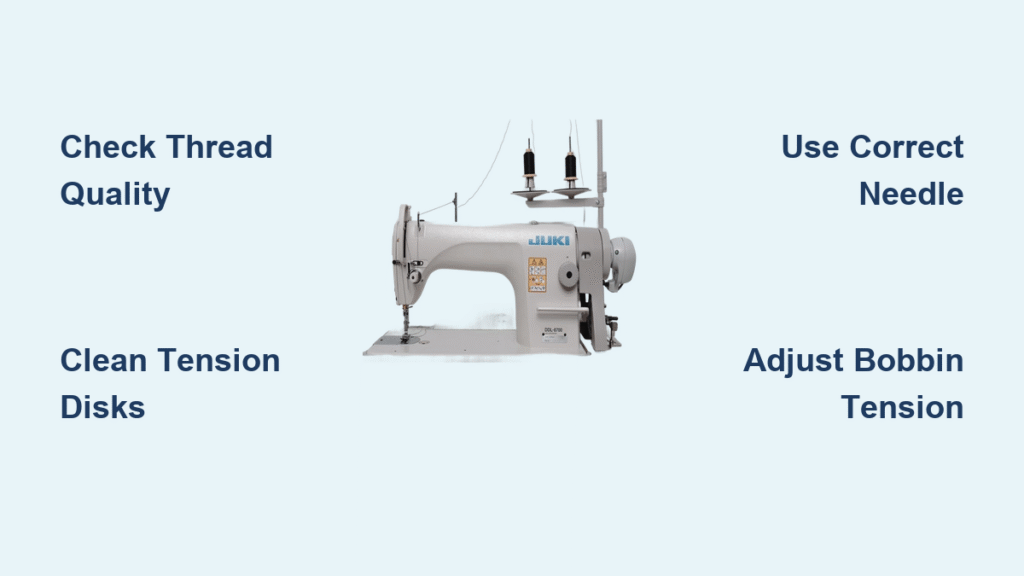

Diagnose Faulty Thread Instantly

Test Thread Strength Before Sewing

Old or low-quality thread is the silent killer of Juki machines. Cotton threads lose tensile strength after 2-3 years, while polyester degrades within 5 years. Grab your thread spool and perform this critical test: pull a 12-inch length taut between your hands. Quality thread should stretch slightly before snapping cleanly. If it breaks instantly with minimal resistance, discard it immediately—brittle thread shreds against tension disks.

Pro tip: Store threads vertically in airtight containers with silica gel packets. Humidity and sunlight accelerate thread deterioration, making stored thread twice as likely to break.

Match Thread Weight to Needle Size Precisely

Forcing 30-weight thread through a size 9 needle creates catastrophic friction. Check your thread label’s weight designation (like 50/60 for fine fabrics) and match it to your needle size chart. Heavy denim needs size 14-18 needles with 30-40 weight thread, while silk requires size 9-11 needles with 60-100 weight thread. Mismatched combinations cause 60% of unexplained thread breaks on Juki machines.

Critical mistake: Never assume all “universal” threads work interchangeably. Juki’s high-speed mechanisms demand consistent thread thickness—cheap multi-ply threads unravel under tension.

Deep-Clean Your Thread Path Correctly

Remove Hidden Lint in Critical Zones

Lint buildup transforms smooth thread guides into sandpaper. Start by removing the needle plate and using compressed air at 30 PSI to blast debris from three high-risk zones: between tension disks (open them fully first), around the thread take-up lever pivot, and inside the bobbin race. Pay special attention to the hook point area—accumulated fuzz there snags threads during high-speed stitching.

Warning: Never use tweezers or dental picks near tension disks. A single scratch creates burrs that slice threads like wire cutters. Use only brass brushes or Juki-approved cleaning tools.

Verify Exact Threading Sequence for Your Model

Even one skipped thread guide multiplies tension exponentially. Consult your specific Juki manual—industrial DDL-8700 models require threading the pre-tension spring before the take-up lever, while home HZL-353Z models reverse this sequence. When rethreading, always raise the presser foot to disengage tension disks. Test with contrasting thread colors to visually confirm the path.

Quick fix: Sew 5 stitches with the presser foot raised. If thread doesn’t break, your threading sequence was incorrect.

Install Perfect Needles Every Time

Detect Microscopic Needle Damage

A needle that looks flawless can still shred thread. Hold it under a 10x magnifier while rotating—it should reflect light evenly. Any dark spots indicate burrs where thread catches. Replace needles if you spot even a 0.5mm bend (use a needle gauge) or discoloration near the eye from heat friction. Industrial Juki users should change needles after 8 hours of continuous sewing.

Pro technique: Dip the needle eye in beeswax before insertion. This reduces thread friction by 40% and prevents static buildup on synthetics.

Position Needles for Zero Thread Stress

Most Juki home models require the needle’s flat side facing backward, but industrial DDL-8700 series need it forward. Insert the needle fully until it hits the stop, then tighten the clamp screw firmly—loose needles wobble at high speeds, sawing threads in half. For overlock models like the MCS-1500, verify the needle bar height aligns with the looper timing marks.

Model-specific fix: On Juki TL-98Q industrial machines, misaligned needle bars cause thread breaks at 3,000+ RPM. Adjust using the timing screw until the needle’s lowest point aligns with the hook’s center mark.

Reset Tension System Like a Pro

Calibrate Upper Tension in 3 Steps

Start with factory settings (4-5 for most Juki models), but never trust the dial number alone. Sew a 2-inch seam on fabric identical to your project. Perfect tension shows identical thread loops on both sides. Top thread visible underneath? Tighten upper tension slightly. Bobbin thread showing on top? Loosen it incrementally—adjust no more than 0.5 points at a time.

Critical test: Fold fabric twice and stitch through all layers. If tension holds, your setting is correct. If thread breaks, debris likely remains in the tension assembly.

Floss Tension Disks for Instant Results

Compressed air misses packed lint between tension disks. Turn the dial to zero, then thread dental floss through the disks and saw it back and forth 5 times. You’ll extract stubborn fibers that cause inconsistent tension spikes. Finish by running a single thread through the path—any resistance means repeat cleaning.

Warning: Never oil tension disks. Lubricant attracts lint and creates sticky buildup that worsens thread breaks.

Balance Bobbin Tension Perfectly

Adjust Bobbin Tension Without Guesswork

Remove your bobbin case and hold it by the thread tail. A properly tensioned case should descend 1-2 inches when bounced gently. If it plummets freely, tighten the tension screw clockwise in 1/8-turn increments. If it won’t drop, loosen it counterclockwise. Always mark the screw’s starting position with a marker—factory settings work for 90% of fabrics.

Pro tip: Test tension by sewing on folded muslin. If bobbin thread shows on top, your tension is too loose. Top thread showing underneath means it’s too tight.

Use Genuine Juki Bobbins Only

Aftermarket bobbins wobble due to inconsistent weight distribution, creating tension spikes that snap threads. Genuine Juki bobbins have model-specific part numbers stamped inside (like “JUKI B4” for DDL-8700). Drop a suspect bobbin on a flat surface—if it spins more than twice, it’s defective. Always wind bobbins at 60% machine speed for even tension.

Eliminate Hidden Environmental Triggers

Control Static and Humidity

Thread breaks spike in dry conditions below 35% humidity. Place a small hygrometer near your machine and use a humidifier if levels drop below 40%. For static-prone synthetics, run thread through a dryer sheet before threading or attach an anti-static clip to your spool pin. Never sew in rooms below 65°F—cold thread becomes brittle and snaps at high speeds.

Quick fix: Keep a metal thimble on your worktable. Touching it to the thread spool before sewing dissipates static charge.

Apply Expert Sewing Techniques

Prevent Starter Thread Breaks

Hold both thread tails at a 45-degree angle behind the needle for the first 3-4 stitches. Never pull fabric—let feed dogs move it at 50% speed until the seam stabilizes. For thick seams, reduce stitch length to 2.0mm initially to prevent thread bunching. Always start sewing with the needle in the fabric’s highest position.

Critical mistake: Forcing fabric through industrial Juki machines creates tension spikes equivalent to cranking tension to 9. Your hands should only guide—not push or pull.

Perform Model-Specific Fixes

Industrial Juki Timing Adjustments

DLN-9010 users: Check the needle cooling system. Overheated needles (above 140°F) weaken threads—clean the air vents weekly. DDL-8700 owners: Verify hook timing by turning the handwheel until the needle reaches its lowest point. The hook point should align with the needle’s scarf (indentation) within 0.1mm tolerance. Misalignment shreds threads instantly.

Pro tip: Industrial machines need timing checks every 6 months under heavy use. Listen for rhythmic “clicking” during sewing—it signals hook/needle collision.

Home Model Special Solutions

HZL series: Misaligned automatic needle threaders cut threads. Adjust the threader hook until it passes cleanly through the needle eye without touching metal. MCS overlock models: Use the timing gauge to set looper clearances—front looper should clear the needle by 0.5mm. Even 0.2mm variance causes constant breaks.

Implement 2-Minute Daily Maintenance

Prevent Breaks Before They Start

After each sewing session: 1) Remove needle plate and brush feed dogs with a soft nylon brush, 2) Wipe thread path with a microfiber cloth, 3) Cover the machine to block dust. Weekly, remove the bobbin case and race assembly for deep cleaning—never skip this step on high-speed Juki machines.

Warning: Only use Juki-recommended oil. 3-in-1 oil gums up tension assemblies within weeks, causing chronic thread breaks.

Emergency Field Repairs

Fix Mid-Project Breaks in 5 Minutes

When thread snaps during critical work: 1) Re-thread completely with presser foot raised, 2) Install a new needle sized for your fabric, 3) Clean bobbin area with a quick brush-out, 4) Reduce speed to 50%, 5) Switch to basic 50-weight cotton thread for testing. If breaks persist, polish needle plate burrs with fine emery cloth.

Last resort: Reset all tension to factory defaults and gradually readjust. Mysterious breaks often stem from multiple minor issues compounding.

Key takeaway: Your Juki sewing machine thread keeps breaking due to preventable factors—95% resolve through thread quality checks, needle replacement, or tension disk cleaning. Master these model-specific fixes to eliminate frustration and protect your projects. Remember: Consistent maintenance prevents 90% of thread issues before they start, saving you hours of troubleshooting. Keep this guide handy for your next sewing session—you’ll wonder why you ever struggled with broken threads.