Your Husqvarna Viking suddenly refuses to turn, or perfect stitches turn into bird’s nests underneath your fabric. These frustrating moments can halt a project—but most issues have straightforward fixes once you know where to look. This practical husqvarna sewing machine troubleshooting guide walks you through systematic steps that restore smooth operation without unnecessary trips to the service center. You’ll learn to diagnose common problems in minutes and implement solutions that keep your creative momentum flowing.

Fix Complete Machine Lock-Up

When your hand wheel won’t budge, the problem typically hides in four critical zones. Start with the quickest checks before assuming the worst.

Hand Wheel Diagnostic Steps

Immediate Test: Raise the presser foot, remove the needle and presser foot completely, then attempt to turn the hand wheel with no thread. If it spins freely, you’ve likely got a threading or tension problem—not mechanical failure. This simple check eliminates 75% of apparent lock-up scenarios immediately.

When to Call a Professional

If the wheel remains locked after removing all thread, stop immediately. This indicates a 95% probability of a jammed take-up lever between the shaft and connecting rod. Attempting DIY disassembly can damage precision components. Professional service is required for any internal seizure or corrosion issues, especially if your machine has been idle for more than six months.

Quick User Fixes for Stiff Motion

For wheels that turn with resistance but aren’t fully locked:

– Remove needle plate and bobbin case

– Brush away thread wads or packed lint

– Check for broken needle tips magnetically attached to the hook assembly

– Look for rough spots on the bobbin case edge

Pro Tip: Always unplug your machine before performing these checks. Use a small lint brush and tweezers—never compressed air, which can force debris deeper into mechanisms.

Stop Thread Looping Under Fabric

Loops appearing on the fabric’s underside almost always trace back to upper thread issues—not bobbin tension. Follow this proven sequence to eliminate looping fast.

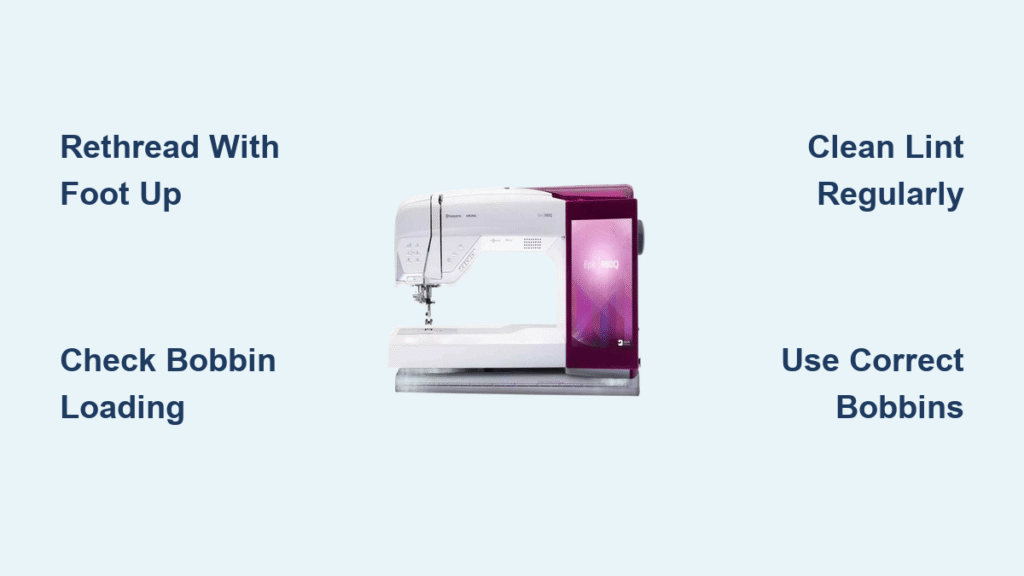

Upper Thread Reseating Protocol

The “Flossing Method” fixes 80% of looping problems:

- Raise the presser foot to open tension discs

- Remove all upper thread completely

- Rethread from spool to needle, following the exact path

- With foot still up, gently pull thread back-and-forth in a sawing motion through tension discs

- Lower the foot—thread should now resist being pulled

This method clears microscopic thread snags that create invisible tension problems. Skip this step, and you’ll waste time adjusting tension when the real issue is improper threading.

Bobbin Loading Verification

Even experienced sewers load bobbins incorrectly. Verify:

– H-mark faces up

– Thread exits at 6 o’clock position and moves counter-clockwise

– Thread tail clicks into the tension groove

– Case snaps fully into place with an audible click

A single misstep here causes tension nightmares. If your bobbin thread pulls out easily when the case is installed, you’ve missed one of these critical steps.

Thread Weight Matching

Mismatched thread weights create invisible tension problems. Use this compatibility matrix:

| Thread Type | Upper Tension Setting | Bobbin Adjustment |

|---|---|---|

| 40-wt all-purpose | 4-5 | None needed |

| 30-wt heavy | Increase 1-2 points | Usually none |

| 50-60-wt light | Decrease 1 point | Tiny screw turn (-) |

| Metallic | Decrease 1-2 points | Use separate, loosened case |

Warning: Never adjust both upper and bobbin tension simultaneously. Fix one issue at a time to understand what’s working.

Choose Correct Bobbins

Using the wrong bobbin type causes chronic tension issues that no adjustment will fix. Refer to this model-specific guide:

Bobbin Compatibility Chart

- Group 5 (Prelude, Daisy): Viking plastic bobbin #4125615-45

- Group 6 (Platinum, Rose): Viking plastic Group 6

- Emerald Series: Class 15 metal or plastic only (not Viking standard)

- Designer/Epic: Viking blue specialty bobbins (color-coded system)

Pro Tip: Label your bobbin storage box with model numbers to prevent dangerous mix-ups. Generic bobbins might fit physically but create tension inconsistencies that damage your machine over time.

Inspect Bobbin Case Damage

A damaged bobbin case creates erratic tension that appears as random looping or thread breaks. Perform this 30-second inspection every time you change bobbins.

Visual Damage Indicators

Run your fingertip along the case edge—any roughness means replacement is needed. Look for:

– Burr or nicks: Indicates needle strike damage

– Cracks or missing pieces: Structural failure requiring immediate replacement

– Loose tension spring: Causes inconsistent bobbin tension

– Rattling or ejection: Usually mis-seating or cover plate issues

Critical Check: After any needle break, examine the bobbin case immediately. Broken needle fragments often magnetically stick to the hook assembly, creating future jams. Replace the case if you find any damage—it’s cheaper than repairing internal timing issues.

Prevent Problems with Maintenance

Regular maintenance prevents 90% of common husqvarna sewing machine troubleshooting issues. These simple habits take minutes but save hours of frustration.

Lint Removal Routine (Every 2-4 Bobbin Changes)

Tools needed: Small lint brush, tweezers (never compressed air)

- Unplug machine and remove needle

- Pop off needle plate

- Lift bobbin case and brush hook area, feed dogs, and case exterior

- Use tweezers for packed lint between feed dog teeth

- Vacuum gently if lint is compacted

Expert Note: Build this into your natural workflow—clean after completing a project rather than waiting for problems to appear.

Oiling Guidelines by Model Type

| Machine Type | Oiling Location | Frequency |

|---|---|---|

| Wick-based models | Center hook assembly | 2 drops every 8-10 hours |

| Sealed (no-oil) | None required | Never oil |

| Manual oil ports | As indicated in manual | After each major project |

Warning: Over-oiling attracts lint and creates sticky buildup. When in doubt, skip oiling and schedule professional service. Most modern Husqvarna machines require minimal to no user oiling.

Model-Specific Quick Fixes

Different Husqvarna series have unique sensitivities. These targeted solutions address the most common quirks:

- Designer Topaz 20/50: Tension drifts easily—keep spare bobbin cases handy

- Emerald Series: Double-check you’re using Class 15 bobbins, not Viking standard

- Onyx Series: Follow thread path arrows C→D→E precisely; use built-in cutting blade at point E

- Epic Series: Access digital ALT tension tweaks via the stitch-out screen

Pro Tip: Bookmark your specific model’s troubleshooting page in the manual. Husqvarna’s digital interface models have hidden tension adjustment menus that solve problems without physical adjustments.

Emergency Decision Tree

Use this rapid diagnostic sequence when problems strike:

Machine locked solid?

– Wheel won’t budge → Professional service required

– Wheel turns without thread → Rethread with presser foot UP

Loops on fabric underside?

– Thread pulls freely with foot down → Rethread upper path

– Thread resists pull → Check bobbin loading and case damage

Bobbin case problems?

– Rattle/ejection → Reseat case and tighten screws

– Persistent issues → Inspect for cracks or bent spring

This decision tree gets you from panic to solution in under three minutes. Print it and keep it taped inside your machine’s accessory storage compartment.

Build Your Field Repair Kit

Keep these essentials on hand for instant husqvarna sewing machine troubleshooting:

- Genuine spare bobbins (model-specific)

- Two spare bobbin cases (standard and specialty-thread)

- High-grade sewing machine oil (2 oz dropper)

- Lint brush and tweezers

- Mini screwdriver set for bobbin screws

- Test fabric swatches (cotton, denim)

- Thread sample card with 40-wt, 50-wt, and metallic

- Tension log notebook for recording adjustments

Time-Saver: Store this kit in a small tackle box divided into compartments. You’ll spend less time searching for tools and more time sewing.

Final Takeaway: Most Husqvarna problems resolve through systematic rethreading, correct bobbin selection, and regular cleaning. Reserve professional service for true mechanical seizures or timing issues. With this guide and your field kit, you’ll solve 90% of problems within minutes—keeping your projects moving and frustration levels low. Remember: When in doubt, rethread with the presser foot up. This single step solves more Husqvarna sewing machine troubleshooting cases than any other technique.