That first whir of your Juki industrial sewing machine can trigger equal parts excitement and anxiety. Unlike home models, these powerhouses demand precise technique to harness their 5,500-stitch-per-minute capabilities without damaging delicate fabrics or causing dangerous needle breakage. Whether you’re operating a DDL-8700 straight-stitch model or a DDL-9000C servo machine, how to use a Juki industrial sewing machine safely and effectively starts with understanding its unique engineering. This guide cuts through the complexity with actionable steps you can implement immediately—transforming intimidating controls into professional results within your first hour of operation. Forget generic manuals; you’ll discover exactly where to place your hands for leather stitching, why bobbin tension differs from home machines, and how to prevent the dreaded bird nesting that wastes hours of production time.

Stable Machine Placement for Precision Sewing

Optimal Work Surface Requirements

Position your Juki on a vibration-free table at 28-30 inches height—critical for maintaining posture during 8-hour shifts. Maintain 2-3 feet of clearance around the machine head for fabric handling and emergency access. Industrial models like the DDL-9000C require solid anchoring; bolt the machine to prevent shifting during heavy denim stitching. Never place near moisture sources or direct sunlight that warps metal components. For production lines, align multiple machines parallel to create efficient workflow paths between stations.

Power Safety Verification Process

Before plugging in, locate the voltage specification plate on your machine’s right side. Match it exactly to your facility’s power supply (110V or 220V single-phase). Use only the three-prong grounded cable—never adapters or extension cords—to prevent electrical shock from the magnetic clutch motor. Test the circuit with a multimeter to confirm stable voltage. If lights dim when starting, consult an electrician; inconsistent power causes premature clutch failure. Always switch OFF before connecting/disconnecting power to protect servo motor circuitry.

Non-Negotiable Safety Equipment Checklist

Protect yourself from industrial hazards with these essentials:

– Safety glasses (ANSI Z87.1 rated) to block needle shrapnel during leather stitching

– Cut-resistant gloves (level 5) for bobbin case handling

– Non-slip footwear to maintain pedal control during high-speed operations

– Hair restraints that fully contain long hair from feed dog mechanisms

– N95 masks when sewing synthetics like polyester that release microfibers

Perfect Threading System Execution

Main Thread Path Setup Without Tangles

Start by placing thread on the rear spool pin with a matching spool cap to prevent wobble. Follow this exact sequence:

1. Thread through the rear guide 6-8 inches above the spool

2. With presser foot RAISED, seat thread between tension discs

3. Thread the take-up lever eye from right to left

4. Insert needle front-to-back, leaving a 4-inch tail

Pro tip: Use colored thread for top and contrasting thread for bobbin—this instantly reveals tension issues on test fabric. If threads loop excessively on the underside, upper tension is too loose.

Bobbin Winding for Jam-Free Operation

Place an empty bobbin on the top-right spindle and wrap thread clockwise 3 times. Engage the winder by pushing it toward the handwheel while holding thread tail. Wind at 25% speed initially for even distribution. Stop when thread fills 85% of bobbin depth—overfilling causes thread jams in the shuttle hook. The winder disengages automatically on DDL series models when full. Trim excess thread cleanly with scissors after disengagement.

Bobbin Case Installation That Prevents Bird Nesting

Open the slide plate beneath the needle and insert the bobbin with thread unwinding counterclockwise. Pull thread through the tension spring slot until it clicks. Hold the thread tail and pull 4 inches through the delivery slot. Insert the case into the shuttle hook with the finger pointing toward you—listen for the secure click. If threads tangle underneath fabric, remove and reinstall the case; improper seating causes 70% of bobbin-related jams.

Control System Precision for Flawless Stitches

Speed Management for Different Fabrics

Master multiple speed controls simultaneously:

– Foot pedal: Press firmly for 5,500 SPM on denim; feather gently for 800 SPM on silk

– Knee lever: Lower under-table lever to slow speed during curve pivoting

– Handwheel: Rotate manually for needle positioning on delicate hems

– Speed limiter: Set mechanical governor to 1,500 SPM for new operators

Expert note: Reduce speed by 30% when sewing through multiple fabric layers—needle deflection causes skipped stitches on heavy materials.

Stitch Length Calibration by Material Type

Adjust the right-side dial while testing on project-matching scraps:

– Denim/leather: 6-8 SPI (4-5mm length)

– Standard cotton: 10-12 SPI (2-2.5mm)

– Silk/chiffon: 15-20 SPI (1.2-1.6mm)

– Basting: Maximum length (5 SPI)

Turn clockwise to increase length. Always verify with a ruler—industrial machines stretch threads at high speeds, making visual estimates unreliable.

Tension Balance System Troubleshooting

Upper tension: Start at setting 4. If top thread shows loops on fabric underside, tighten in quarter-turn increments. If bobbin thread shows on top surface, loosen. Bobbin tension: Access the case screw—turn clockwise 1/8 turn to increase. Mark factory position with nail polish before adjusting. Test tension by holding bobbin thread; it should drop 6-8 inches with a gentle shake.

Daily Operation Sequence for Production Efficiency

Pre-Sewing Checklist to Avoid Costly Mistakes

Complete these steps before every project:

1. Match needle type to fabric (size 14 for cotton, 22 for leather)

2. Verify thread weight compatibility (T-90 thread for size 18 needle)

3. Confirm bobbin tension by testing on scrap

4. Adjust presser foot pressure for fabric weight

5. Clean feed dogs with lint brush

Skipping this 60-second routine causes 80% of operational failures according to factory technicians.

Starting Seams Without Thread Tangles

Position fabric with 1/2-inch seam allowance using the machine’s needle plate markings. Hold both thread tails behind the presser foot. Start with 3 reverse stitches at reduced speed, then sew forward while guiding fabric at 3 and 9 o’clock positions. Never pull fabric—let the feed dogs move material. For leather, place a Teflon foot under the fabric to prevent sticking.

Fabric Handling Techniques by Material Type

Denim/leather: Increase presser foot pressure, use size 20 needle, and reduce speed to 800 SPM. Support fabric weight with your left hand to prevent needle deflection. Silk/stretch knits: Decrease pressure, use size 11 ballpoint needle, and maintain even feeding without stretching. Pivot curves by stopping with needle down, then rotate fabric. Always backstitch at seam ends for security.

Advanced Feeding Systems for Challenging Materials

Drop Feed System Optimization

Standard on DDL-8700 models, adjust feed dog height via the rear screw:

– Light fabrics: Lower feed dogs to minimize puckering

– Heavy materials: Raise for aggressive fabric movement

– Free-motion quilting: Disengage completely by turning feed dog lever

Clean feed dogs daily with a stiff brush—lint buildup causes inconsistent feeding on stretch fabrics.

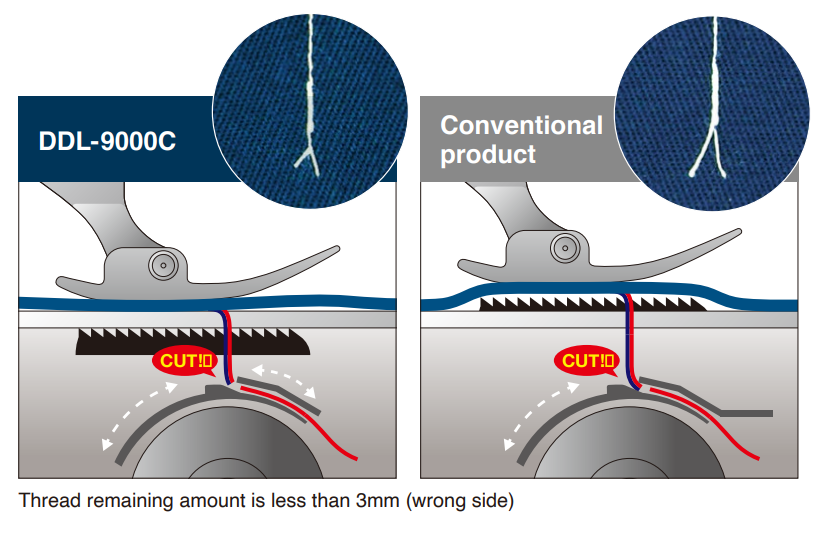

Needle Feed System for Upholstery Success

The DDL-9000C’s synchronized needle/feed movement prevents layer shifting on vinyl and leather. Activate by engaging the needle-feed lever on the machine head. Use size 22 needles with T-135 thread at 600 SPM. This system eliminates the need for walking feet on materials up to 1/4-inch thickness.

Maintenance Excellence for 10,000+ Hour Lifespan

Daily Cleaning Routine That Prevents Downtime

Before use: Brush lint from bobbin case and feed dogs. Check oil levels through the sight glass—top up if below minimum mark. During operation: Stop immediately for unusual noises or thread breaks. After use: Cover machine, release thread tension, and log hours for oil changes. Machines cleaned daily run 40% cooler according to Juki service data.

Lubrication Management by Machine Model

Use only Juki-approved oil in these critical points:

– DDL-8700: Oil hook race daily, needle bar weekly

– DDL-9000C: Oil servo motor bearings monthly

– LU-1508N: Oil walking foot mechanism weekly

Change oil every 1,000 hours or 6 months. Over-oiling attracts lint—add drops slowly until sight glass shows mid-level.

Troubleshooting Common Production Issues

Thread Breakage Solutions in Under 2 Minutes

Replace the needle first—90% of thread breaks stem from dull or bent needles. Verify thread path freedom from snags using a magnifying lamp. Clean tension discs with dental floss. If breaks persist, switch to high-quality polyester thread; cotton thread shreds at industrial speeds.

Skipped Stitches Prevention on Knits

Use fresh stretch needles (size 14 ballpoint) inserted with flat side facing away. Reduce presser foot pressure by 25% and increase stitch length to 12 SPI. If skipping continues, check needle-to-hook timing—consult your service manual for model-specific adjustment procedures.

Specialized Applications Mastery

Leather Sewing Protocol for Professional Results

Use size 22 leather-point needles changed every 4 hours. Pre-wax T-135 nylon thread to reduce friction. Set presser foot pressure to maximum, stitch length to 6 SPI, and speed to 500 SPM. Always use a roller foot to prevent leather from sticking to the needle plate. Test settings on scrap hide before starting production.

Stretch Fabric Techniques Without Puckering

Install a new size 11 stretch needle with the flat side toward you. Set presser foot pressure to minimum and stitch length to 14 SPI. Use polyester thread with 20% stretch. Guide fabric gently—applying even 1 pound of pressure causes visible puckering on knits. Backstitch only at seam ends to maintain elasticity.

Mastering how to use a juki industrial sewing machine transforms intimidating equipment into your most reliable production asset. Start with medium-weight cotton using factory tension settings, then gradually progress to challenging materials as you build confidence. Remember: consistent daily maintenance prevents 90% of operational failures—spend those 5 minutes cleaning, and your machine will deliver flawless stitches for decades. When in doubt, always test settings on project-matching scraps; this single habit separates amateur operators from production-floor professionals.