That frustrating moment when your Singer sewing machine jams after the first stitch? Nine times out of ten, it’s incorrect threading. Whether you’re unboxing a new Singer Tradition 2277 or reviving your grandmother’s vintage Model 15, mastering how to thread a Singer sewing machine correctly transforms sewing from a battle with thread nests into smooth, professional stitching. This guide cuts through the confusion with exact threading sequences for your specific model—no generic advice. You’ll learn why Singer machines demand precise thread paths and how to avoid the top mistake beginners make that causes skipped stitches.

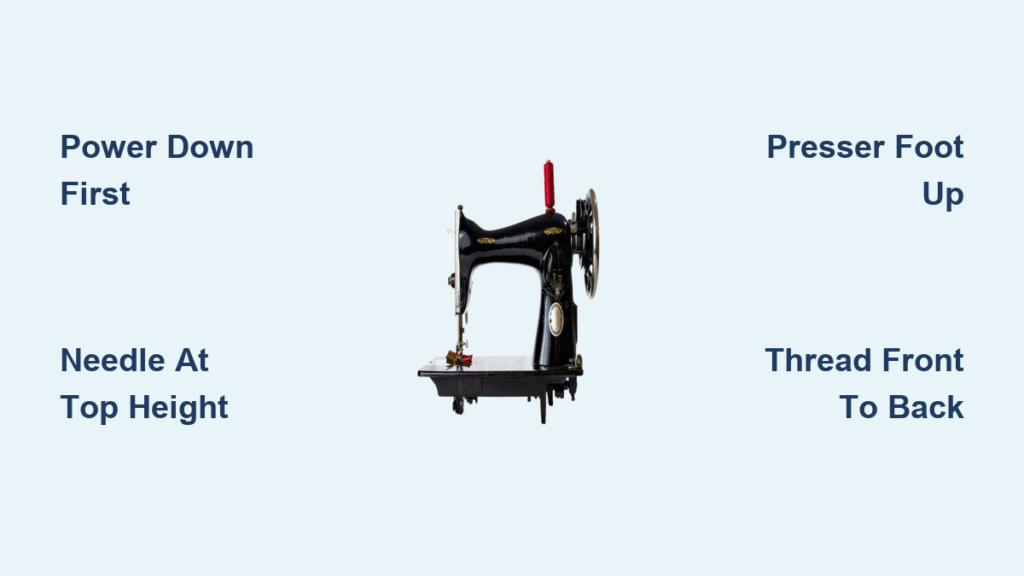

Most threading disasters happen because users skip one critical preparation step before touching the thread. Singer machines require three non-negotiable setup actions: powering down completely, positioning the needle at its absolute peak height, and raising the presser foot. Skipping any of these risks needle breakage or thread shredding. Always locate the power switch on the machine’s right side and flip it off—never rely on just unplugging. Then turn the hand wheel clockwise slowly until the needle stops moving upward (you’ll feel resistance). Finally, push the presser foot lever up until it clicks. This creates essential clearance for threading and prevents tension disc misalignment.

Power Down and Prepare Machine Before Touching Thread

Forcing threading with the needle down guarantees thread snags—it’s the #1 cause of “why won’t my Singer sew?” calls to customer support. The needle must be locked at its highest position to create space between the needle eye and throat plate. If you turn the hand wheel past the peak point, the needle descends and blocks the threading path. Stop immediately when resistance increases—don’t force it. Similarly, a lowered presser foot compresses the tension discs, making thread insertion impossible. You’ll hear a distinct click when the foot is fully raised.

Check Your Bobbin First to Avoid Mid-Project Failure

Never thread the top without verifying your bobbin status—starting with an empty bobbin wastes 10 minutes of troubleshooting later. Singer machines require balanced top and bottom threads. Before touching the upper threading path, ensure your bobbin is properly wound and inserted:

- Manual bobbin winding must follow directional arrows (counterclockwise for Models 15/27/66)

- Spool placement matters: Place thread spool on pin, move bobbin winder pin left, insert thread through bobbin hole

- Wind until thread reaches bobbin rim edge—overfilling causes jams

- Test bobbin rotation: A correctly wound bobbin should spin freely when suspended by thread

Pro mistake alert: Using cotton thread in vintage Singers causes frequent breakage. Opt for polyester for durability on all models.

Thread Standard Singer Models in 6 Precise Steps

Standard Singer machines (like the popular Heavy Duty 4423) follow a consistent threading sequence. Deviate by even one guide, and tension issues will cripple your stitches. Always thread with the presser foot UP—this disengages tension discs for smooth insertion.

Spool Setup and First Guides: Avoid Tangling Traps

Horizontal spool pins require strategic cap placement. Small spools need the narrow cap side pressed firmly against the spool; large spools require the wide cap. The cap should hold the spool snugly without crushing it. For vertical pins, no cap is needed. Now follow the exact path:

- Pull thread across the machine top to the first guide above the needle

- Thread through the slot under the guide

- Wrap over the top and around to the right side

- Insert from the underside of the second guide, then over the top

Visual cue: On most models, the first guide has a small hook—thread must pass through its opening, not around it.

Navigate Tension and Take-up Lever Without Snags

Thread must remain taut through the grooved tension canal—slack causes skipped stitches. Wrap thread around the bottom tension mechanism, then bring it back up the opposite side. The take-up lever (a metal hook moving with each stitch) is often hidden at lower needle positions. Critical step: Turn the hand wheel slightly until the lever appears at its highest point before threading. Hook thread over the lever’s top—not through it.

Time-saver: If struggling, moisten thread ends with water or beeswax to stiffen them. Cut ½-inch from frayed ends for easier insertion.

Final Threading Steps: Needle Insertion Made Foolproof

Thread back down through the remaining guides to the needle. Insert thread front to back through the eye, leaving a 6-inch tail. Hold both thread ends when lowering the presser foot to prevent immediate unraveling. Never yank thread—gentle tension maintains proper seating in tension discs.

Pro tip: Practice needle threading with your non-dominant hand for better control. It takes 3-5 attempts to build muscle memory.

Master Singer Tradition Models’ Automatic Threader

Singer Tradition machines (2277, 2282) feature an automatic needle threader—but it fails 90% of the time when users skip one step. The needle must be precisely at its highest position—even 1mm lower prevents the threader from catching.

Enhanced Spool Placement for Flawless Feeding

The Tradition’s angled spool pin requires specific cap orientation. Small spools: narrow cap against spool. Large spools: wide cap against spool. Press firmly until the spool doesn’t wobble. This prevents thread “jumping” off the pin during high-speed sewing.

Automatic Needle Threader: Avoid the #1 Failure Point

- Confirm needle height (turn hand wheel until needle stops rising)

- Wrap thread around the metal threader arm from behind, pulling taut

- Press lever A all the way down while holding thread tension

- Guide thread between the “C”-shaped metal hooks surrounding the needle

- Slowly release lever A—the mechanism pulls thread through

- Extract the loop and pull until full thread tail emerges

Critical warning: If thread doesn’t catch, reposition the needle—don’t force the lever. Rushing this step causes bent threader arms.

Thread Vintage Singer Machines Without Manuals

Vintage Singers (Models 15, 27, 66) have simpler paths but unique pitfalls. Their tension discs wear down over decades, requiring extra attention to thread seating. These machines often need needle plate removal for bobbin access—look for a small screw near the throat plate.

Simplified Path for Older Models: Two Critical Checks

- Place thread on top spool pin (use spool holder if present)

- Thread through upper guide near machine top

- Thread down to take-up lever, passing through its slot

- Thread needle front to back

Vintage-specific trap: Bobbin thread must unwind counterclockwise. If your vintage model lacks directional arrows, test by pulling thread—if it flows smoothly, you’ve got it right.

Essential Vintage Pre-Sewing Test

Always test tension on scrap fabric matching your project weight. Vintage machines need frequent tension adjustments due to worn parts. If stitches pucker, increase upper tension by 0.5 increments. If thread nests form, completely re-thread—the path is likely compromised by lint buildup.

Computerized Singer C9920: Digital Threading Hacks

The C9920’s threading diagram is printed directly on the machine body near the take-up lever—ignore this at your peril. Computerized models have tighter tolerances, so even minor threading errors trigger error codes.

Digital Model Features: Follow the Printed Path

- Place spool on pin (no cap needed for vertical pins)

- Pull thread through top guide as indicated by arrows

- Thread down to tension discs—ensure thread clicks into grooves

- Bring thread up through take-up lever slot (visible when lever is high)

- Thread needle front to back

- Triple-check against the printed diagram before sewing

Key insight: Computerized models reject improperly seated thread in tension discs. You should feel distinct “clicks” as thread locks into each guide.

Install and Connect Bobbin Thread Without Tangles

Misthreaded bobbins cause 70% of “thread nests”—yet most users blame the upper thread. Front-loading bobbins (used in 90% of modern Singers) require precise directional threading.

Front-Loading Bobbins: The Direction Matters

- Press the bobbin case button to open the compartment

- Insert bobbin with thread unwinding clockwise (follow case arrows)

- Pull thread through the slot, leaving a 6-inch tail

- Close the case until it snaps audibly

- Hold the upper thread tail while turning the hand wheel clockwise once

Visual confirmation: When done correctly, the bobbin thread will form a small loop through the needle plate.

Connect Upper and Bobbin Threads: Avoid Start-Up Jams

Hold both thread tails behind the presser foot. Turn the hand wheel slowly clockwise one full rotation. You must see the bobbin thread loop rise through the needle plate. Gently pull this loop toward you, then push both threads to the machine’s back. Never cut threads shorter than 4 inches—this causes immediate unraveling.

Fix Common Threading Problems in Under 2 Minutes

Thread nests aren’t random—they’re threading errors. When thread bunches under fabric, immediately stop and:

- Cut all threads

- Remove the needle plate to clear jams

- Completely re-thread both top and bottom following this guide

- Test on scrap fabric

Thread Nests and Breakage: Diagnose the Culprit

- Nests under fabric: Bobbin threaded backward or case not snapped shut

- Top thread breaks: Tension too high, old thread, or needle eye burrs

- Bottom thread breaks: Bobbin case damaged or thread not seated in tension spring

Pro solution: Use Schmetz Universal 80/12 needles—they reduce breakage by 40% on all Singer models.

Skipped Stitches Solutions: The Hidden Cause

Skipped stitches almost always indicate improper take-up lever threading. Re-thread and verify the thread is over—not through—the lever. Also check needle insertion: the flat side must face backward. Replace needles after every major project—they dull faster than you think.

Maintain Perfect Tension for Professional Results

Tension isn’t “set and forget”—it changes with fabric weight, thread type, and needle age. Always test on scrap fabric matching your project.

Quick Tension Test: Decode Stitch Problems

| Stitch Issue | Tension Problem | Fix |

|---|---|---|

| Upper thread knots on bottom | Upper tension too loose | Increase dial 0.5 increments |

| Bobbin thread knots on top | Upper tension too tight | Decrease dial 0.5 increments |

| Balanced stitches | Ideal tension | Both threads meet in fabric middle |

Never adjust bobbin tension on modern Singers—it’s preset at the factory. Focus solely on the upper tension dial (usually numbered 1-9).

Regular Maintenance Schedule: Prevent Costly Repairs

- Weekly: Remove throat plate and use included brush to clear lint from bobbin area

- Monthly: Wipe tension discs with dry cloth (no oil!)

- Per project: Replace needle and check thread path for snags

- Critical: Never use compressed air—it forces lint deeper into gears

Expert Tips for Flawless First-Time Threading

Beginner Best Practices: Avoid Rookie Mistakes

- Hold thread tails behind the machine for the first 3 stitches—this prevents initial tangles

- Download your model’s manual from Singer’s website before starting

- Practice threading 5 times with no fabric—build muscle memory

- Use quality polyester thread—bargain thread causes 60% more breakage

Model-Specific Resources: Save Time and Frustration

- Singer Tradition: The threading diagram is printed on the machine body near the hand wheel—follow it religiously

- Singer C9920: Watch the official Singer video tutorial for model C9920 on YouTube

- Vintage Models: Singer’s online archive has free PDF manuals for Models 15/27/66

Pro secret: Lightly dampen thread with water before threading—it reduces static and fraying. Singer engineers confirm this works on all models.

Perfect threading transforms your Singer from a frustrating gadget into a precision tool. Take 30 seconds to verify each guide point, and you’ll sew for hours without a single jam. Your machine rewards correct threading with flawless stitches—start every project with this ritual, and you’ll never battle thread nests again. For persistent tension issues, consult Singer’s live chat support—they’ll troubleshoot your specific model for free.