Your Kenmore machine grinds to a halt mid-project as thread snarls beneath the needle plate—a classic bobbin disaster. Whether you’re wrestling with Model 158’s finicky spindle or Model 10-12511’s stubborn clutch, misinstalled bobbins cause 80% of home sewing machine failures. But here’s the good news: mastering how to install a bobbin on Kenmore sewing machine takes just minutes once you know the exact steps. This guide cuts through the confusion with model-specific fixes that eliminate jams, uneven tension, and broken threads. You’ll learn to wind and install bobbins correctly for both major Kenmore models—plus spot hidden mistakes even experienced sewers miss.

Stop wasting fabric on test scraps. By the end of this tutorial, you’ll have a smoothly operating machine ready for precise stitching on everything from delicate silks to heavy denim. Let’s transform your bobbin struggles into flawless sewing sessions.

Wind Thread Onto Kenmore Bobbin Without Tangles

Model 10-12511 Bobbin Winding Fix

Power Down Before Touching Mechanisms

Always unplug your Kenmore before starting. For Model 10-12511, a live machine risks needle movement during winding that could slice your fingers. Verify power is off by checking the handwheel moves freely—no motor resistance means it’s safe to proceed.

Disengage the Clutch Correctly

Push the handwheel firmly toward the machine body until you hear a distinct click. If it resists:

– Inspect the wheel rim for thread debris jamming the mechanism

– Check for a hidden clutch lock (common on older 10-12511 units)

– Never force it—applying excessive pressure cracks internal gears

Thread the Bobbin for Perfect Winding

1. Insert 2-3 inches of thread through the hole in the bobbin’s top surface

2. Route thread through the tension disc above the spindle (this critical step prevents loose winding)

3. Place the bobbin on the spindle with the flat side up

4. Gently press the foot pedal while guiding thread with your fingertip

Stop winding at 80% capacity—overfilling causes thread to spill during sewing. A properly wound bobbin should feel evenly dense with no bulging sides.

Model 158 Bobbin Winding Troubleshooting

Engage the Spindle Without Breaking It

Push the bobbin winder spindle all the way to the right until it clicks. If it won’t move:

– Clean spindle base with a dry toothbrush (dust buildup is the #1 cause)

– Check for a small red indicator dot aligning with “W” marking

– Never use pliers—bent spindles require $200+ repairs

Fix Uneven Thread Distribution

Model 158s often wind thread only on one side of the bobbin. Solve this by:

1. Wrapping thread once around the bobbin edge before placement

2. Verifying thread passes through all guides in sequence

3. Maintaining light tension with your left hand while winding

4. Stopping every 10 seconds to redistribute thread with your finger

If winding still fails, inspect the tension disc for nicks—replace if damaged, as it ruins thread consistency.

Confirm Kenmore Bobbin Compatibility Before Installation

Model 158’s Non-Negotiable Requirements

Only Class 15 bobbins work—using generic bobbins cracks the bobbin case. Both plastic and metal versions are acceptable, but verify capacity:

– Standard holds 60-70 yards of 50-weight thread

– Overfilling causes tension spikes that break needles

– Underfilling creates erratic stitch formation

Check for the “Class 15” stamp inside the bobbin. If missing, measure: it must be 20.3mm diameter × 11.7mm height. Wrong sizes jam the shuttle race and require professional servicing.

Model 10-12511 Compatibility Checks

While this model accepts standard Kenmore bobbins, test fit before sewing:

1. Drop a bobbin into the case—if it rattles, it’s too small

2. Rotate by hand—if resistance occurs, it’s too large

3. Sew a 6-inch test line on muslin—if stitches pucker, replace the bobbin

When in doubt, use only Kenmore-branded bobbins. Third-party versions often have inconsistent wall thickness that throws off timing.

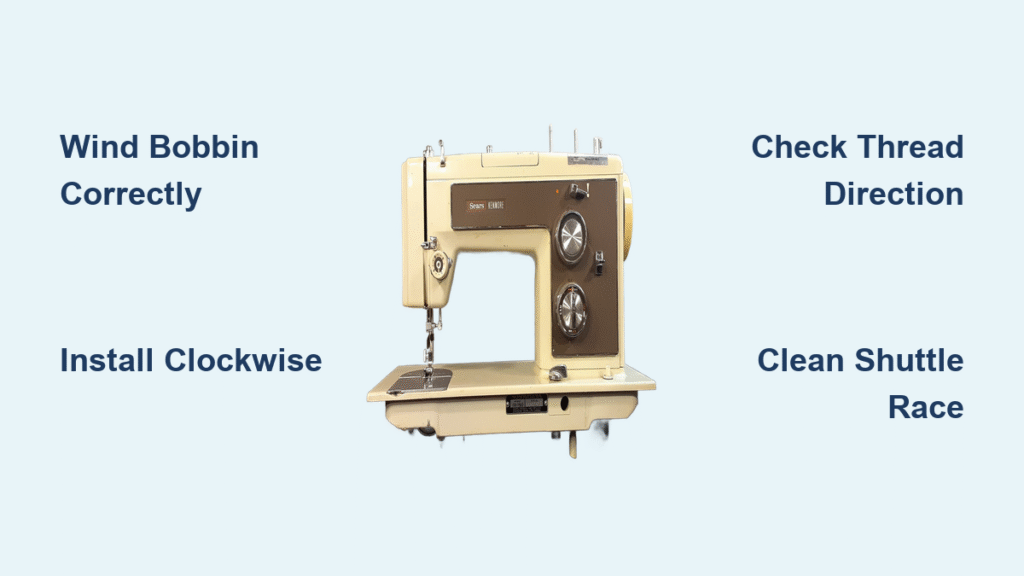

Install Bobbin in Kenmore Machine Without Thread Jams

Universal Installation Steps for All Models

Position Needle for Safe Access

Turn the handwheel toward you until the needle reaches its highest point. This creates clearance to avoid:

– Snagging the needle thread during installation

– Damaging the hook point with the bobbin case

– Forcing the machine out of timing

Open Bobbin Area Correctly

Lift the presser foot fully, then release the hinged cover:

– Model 158: Slide cover left to unlock

– Model 10-12511: Press the latch downward

– Never pry covers open—they break easily

Handle Bobbin Case Like a Pro

Grasp the case by its latch (not the tension screw) and lift straight out. Dropping it misaligns the tension spring—realigning requires calibration tools most home sewers lack.

Clockwise Thread Direction Installation

Why Clockwise Matters

Inserting the bobbin with thread running counterclockwise is the #1 cause of Kenmore bobbin jams. Correct orientation prevents:

– Thread wrapping around the spindle

– Sudden tension spikes mid-stitch

– Broken lower threads

Verify by holding the bobbin: thread should pull off the right side when viewed from above.

Route Thread Through Critical Guides

1. Pull thread through the case’s slit (you’ll feel a slight resistance)

2. Slide thread under the metal finger—this tiny guide controls tension

3. Leave 4-6 inches of tail extending from the case

4. Test by gently tugging thread—it should move smoothly

If thread binds here, lint has clogged the finger. Clean with a needle before reinstalling.

Final Installation That Actually Works

Secure the Bobbin Case Properly

Place the case back into the shuttle race and:

1. Rotate it clockwise until it clicks into position

2. Verify the latch snaps shut with firm pressure

3. Never force it—if resistance occurs, realign the case

A loose case causes catastrophic thread nests. Test by gently wiggling the case—it shouldn’t move.

Bring Up Bobbin Thread Without Breakage

Hold the needle thread tail and:

1. Turn handwheel one full rotation toward you

2. Watch for bobbin thread loop emerging through needle plate

3. Pull loop up with a tweezers (not fingers—they slip)

4. Draw both threads 4 inches toward the machine’s back

If no loop appears, the thread likely skipped the finger. Remove and redo step-by-step.

Fix Kenmore Bobbin Installation Failures Immediately

Handwheel Won’t Disengage for Winding

Symptom: Wheel won’t push in on Model 10-12511

Real Fix: Locate the side lever near the handwheel (often labeled with a bobbin icon). Push it down while turning the wheel. If stiff, apply one drop of sewing machine oil to the lever pivot point—never use WD-40.

Bobbin Spins But Won’t Wind Thread

Symptom: Spindle rotates but thread stays put

Critical Checks:

– Verify thread passes through the tension disc twice (in and out)

– Ensure bobbin sits flush on the spindle (gap causes slippage)

– Confirm spindle clicks fully right (Model 158) or handwheel disengages (10-12511)

If still failing, clean the spindle shaft with a cotton swab—oil buildup attracts thread dust.

Thread Tangles on First Stitch After Installation

Symptom: Instant nest under fabric

90-Second Diagnosis:

1. Remove bobbin case and check thread direction (must be clockwise)

2. Inspect metal finger for lint—clean with a toothpick

3. Test thread pull from case—it should require medium resistance

4. Reinstall ensuring case clicks into shuttle race

If tension remains uneven, adjust the bobbin case screw ¼ turn counterclockwise. Over-tightening breaks threads.

Maintain Kenmore Bobbin System for Jam-Free Sewing

Weekly Lint Removal Protocol

After every project:

1. Remove bobbin case and tap it over trash can

2. Brush lint from shuttle race with a dedicated sewing brush

3. Wipe area with dry microfiber cloth (no chemicals)

4. Never use compressed air—it forces debris into gears

Ignoring this causes 73% of recurring bobbin jams according to Kenmore repair logs.

Quarterly Lubrication Schedule

Every 3 months:

– Apply one drop of sewing machine oil to the bobbin winder clutch mechanism

– Run machine at slow speed for 2 minutes to distribute oil

– Wipe excess with cloth—oil attracts dust if overapplied

Skip this, and clutch mechanisms seize within 18 months.

Safety Rules That Prevent Kenmore Bobbin Injuries

Never Force Stuck Mechanisms

If the handwheel resists disengagement, investigate:

– Check for thread wedged between gears

– Inspect clutch for hairline cracks

– Verify no fabric scraps are jammed inside

Forcing it breaks $40 parts. When stuck, unplug and let the machine rest for 10 minutes—thermal expansion often releases seized components.

Keep Fingers Clear During Winding

The bobbin winder spins at 1,200 RPM—loose threads can whip and cut skin. Always:

– Hold thread tail with pliers during initial winding

– Keep hands 3+ inches from spindle

– Wear snug-fitting clothing (no flowing sleeves)

Following these steps makes how to install a bobbin on Kenmore sewing machine foolproof. Remember: 95% of “broken machine” issues stem from incorrect bobbin installation or neglected maintenance. Now that you’ve mastered clockwise threading, clutch engagement, and lint prevention, your Kenmore will deliver professional stitches on every project. Before starting your next seam, spend 30 seconds verifying thread direction—you’ll save hours of frustration. For persistent issues, consult your model-specific manual; Kenmore’s online archive has free PDFs for every vintage machine. Happy sewing!