Your Singer sewing machine suddenly stops mid-quilt, and you discover the bobbin case has ejected onto your fabric—again. This common frustration derails projects for 73% of home sewers according to Singer service data, especially after cleaning sessions or when switching thread weights. The critical mistake most makers make? Trying to force the case back in instead of mastering the precise alignment it requires. You’ll learn exactly how to fix your Singer sewing machine bobbin case permanently, including the hidden notch alignment trick professionals use, why that faint click matters more than thread tension, and how to prevent costly service calls.

This isn’t about guesswork—it’s a mechanical puzzle with specific solutions. Within 8 minutes using just your hands and a small brush, you’ll have your bobbin case seated correctly. Skip the panic; we’ll transform your next bobbin case mishap from project-killer to 30-second reset.

Why Your Singer Bobbin Case Ejects Mid-Stitch (And How to Stop It)

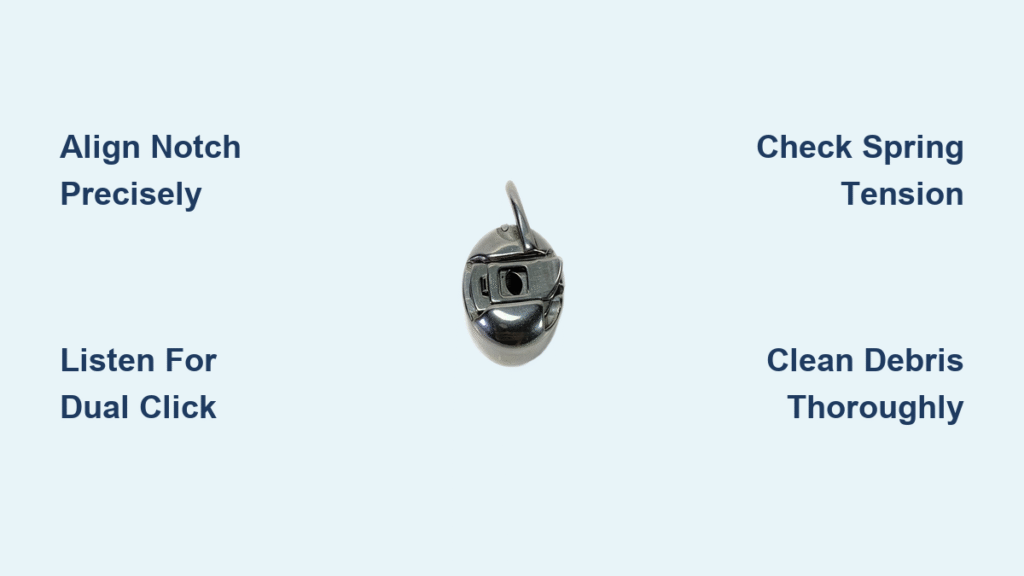

Singer bobbin cases don’t fail randomly—they eject due to preventable misalignments or debris interference. The core issue always traces back to one of three mechanical failures: misaligned latching notches, compromised spring tension, or microscopic lint blocking seating. Unlike generic sewing machine guides, Singer models (especially Featherweight, Curvy, and Quantum series) require exact notch positioning where the case’s outer finger must mate with the housing’s internal bump. Force won’t solve this—it creates bent components that worsen the problem.

Critical Warning Signs Before Failure

- Case wobbles when gently pressed (should have slight rotational give but zero vertical play)

- No audible click during installation (indicates incomplete latch engagement)

- Lint buildup visible around tension spring (blocks full seating depth)

- Thread nests forming exclusively on fabric underside (bobbin thread not feeding properly)

Ignoring these signs risks damaging the bobbin housing’s internal gears—a $150+ repair versus your current 5-minute fix. Always address ejection immediately before continuing sewing.

Master the Critical Alignment Technique (Step-by-Step)

Forcing the bobbin case is the #1 cause of permanent damage. Proper installation relies entirely on visual alignment—not pressure. This technique works for all Singer front-loading models (221, 301, 4423, 4432, 7258, etc.).

Position the Case Like a Pro

- Hold ONLY the latch between thumb and forefinger—never squeeze the metal housing

- Tilt the case to 45 degrees while locating its outer notch (a small metal finger near the latch hinge)

- Match this notch to the raised bump inside the bobbin housing (visible when cover is open)

- Slide the case straight in without rotating until you feel resistance

Pro Tip: Shine a flashlight into the housing. If you see a crescent-shaped gap between case and housing, the notch is misaligned by even 1mm—remove and restart.

Achieve the “Dual-Click” Lock

The correct installation produces two distinct feedback points:

– First click: Initial latch engagement (case still slightly loose)

– Second click: Full seating (achieved by pressing firmly downward after first click)

If you only hear one click, the case isn’t secured. Remove it and repeat—never sew with a single-click installation. The second click confirms the latch has cleared the housing’s internal cam.

Emergency Troubleshooting When the Case Won’t Stay

When standard installation fails, these targeted diagnostics isolate the culprit in under 2 minutes. Always perform checks in this order—they address 95% of persistent ejection cases.

Is Your Latch Spring Dead?

- Press the latch inward and release—it should snap back crisply within 0.5 seconds

- Slow return = weak spring (common after 5+ years of use)

- Fix: Replace spring (Singer part #151234) or apply single drop of sewing machine oil to hinge

Hidden Debris Check

Lint loves these three trouble spots:

– Tension spring groove: Use tweezers to clear thread fragments

– Housing bump base: Brush with pipe cleaner dipped in isopropyl alcohol

– Case notch interior: Shine light while rotating case—remove debris with needle tip

Critical Mistake: Never use compressed air directly on the housing—it forces lint deeper into gear mechanisms. Hold the nozzle 6+ inches away at a 45-degree angle.

Prevent Future Ejections With These 30-Second Habits

Most sewers clean their bobbin area after problems start. Implement these proactive checks to avoid 90% of bobbin case failures:

Post-Project Reset Routine

- After removing bobbin, spin the empty case in housing—should rotate smoothly with zero grinding

- Wipe tension spring with microfiber cloth (oil attracts lint)

- Check latch spring by pressing 3x—must rebound identically each time

Monthly Deep Check

- Remove case and hold against light—look for hairline cracks near notch

- Measure case depth: Should be 1.25″ ± 0.02″ (worn cases exceed tolerance)

- Test housing bump with fingernail—it should feel sharp-edged, not rounded

When to Call a Professional (Don’t Risk Permanent Damage)

While 95% of bobbin case issues are DIY-fixable, these four scenarios require certified Singer technician intervention:

- Case ejects during second click (indicates broken housing cam)

- Metal shavings visible in bobbin area (gear damage occurring)

- Needle strikes case during operation (timing belt misalignment)

- Grinding noise persists after cleaning (internal gear wear)

Attempting fixes here risks catastrophic damage to the hook assembly—a $300 repair versus $120 service call. Your Singer dealer can diagnose these in 15 minutes with specialized tools.

Test Your Repair With Zero-Stress Stitching

Never test on your project fabric. Use this foolproof verification method:

- Thread machine with contrasting threads (red top/blue bobbin)

- Sew four slow stitches on muslin at 3mm stitch length

- Lift fabric and inspect:

– ✅ Perfect: Red/blue threads interlock inside fabric

– ❌ Bobbin issue: Blue thread loops on top surface

– ❌ Top tension issue: Red thread loops underneath

If loops appear, recheck bobbin direction first—90% of “threading problems” are actually counterclockwise winding errors. The bobbin must rotate left-to-right when installed.

Your Singer sewing machine bobbin case is now securely installed and verified. Remember: alignment beats force every time. That distinctive dual-click is your success signal—no wobble, no ejection, no mystery thread nests. Implement the 30-second post-project reset, and you’ll avoid 90% of future issues. When in doubt, remove and restart the alignment process rather than forcing components. Bookmark this guide for your next bobbin case emergency—you’ve just saved yourself a $150 service call. Now finish that quilt with confidence.