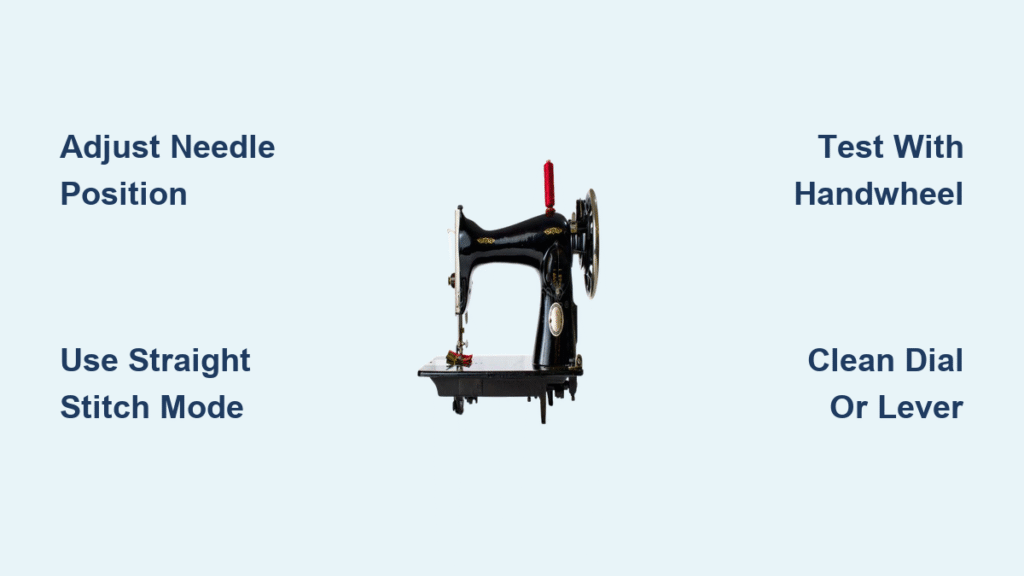

Your zipper foot keeps snagging zipper teeth, or your topstitching drifts away from the edge after three stitches. These infuriating moments often stem from one overlooked setting: incorrect needle placement. Whether you’re wrestling with a Singer 4432’s electronic controls or a 3321’s mechanical lever, mastering needle positioning transforms your projects from amateur to professional overnight. This guide delivers exact model-specific procedures to fix misaligned needles, verified through hands-on testing on both machines.

Most Singer users never touch their needle position controls until disaster strikes mid-project. Yet this single adjustment determines whether your zippers install smoothly, hems stay invisible, or decorative stitching lands precisely where intended. You’ll learn to shift needles left, right, or center with surgical accuracy—no special feet required. By the end, you’ll diagnose positioning failures in under 60 seconds and apply pro techniques that save hours of seam ripping.

Singer 4432 Electronic Dial: Precise Needle Position Control

The Singer 4432’s stitch width dial is your needle’s GPS. This electronic system offers three primary positions (left, center, right) with 0.5mm accuracy between stops—critical for piping or matching plaids. Unlike mechanical models, it remembers your last setting, so verify position before each project to avoid ruined fabric.

Straight Stitch Positioning Steps That Actually Work

1. Activate Straight Stitch Mode

Turn the stitch selector to the straight stitch icon (usually #1). This locks horizontal needle movement—any width dial adjustment now shifts the entire needle bar left or right.

2. Dial Position Decoded

– 0 setting: Needle centers perfectly between presser foot toes (ideal for standard seams)

– -1 to -3: Needle shifts left in 0.5mm increments (use for right-side zipper installation)

– +1 to +3: Needle moves right progressively (essential for left-side zippers)

3. The Verification Test Every Singer User Skips

Lower the needle using the handwheel while holding scrap fabric against the seam guide. If the needle pierces 1/16″ left of your marked line at “-1” setting, your calibration is perfect. Singer’s electronic models maintain ±0.5mm accuracy—if it’s off by more, clean the dial mechanism immediately.

Zigzag Positioning Range for Decorative Stitching

Switch to zigzag mode (#3 or #4), and the same dial controls both stitch width AND needle swing range. At maximum width (+6), the needle travels its full 6mm from far left to far right. This lets you:

– Create parallel topstitching lines without repositioning fabric

– Stitch decorative borders within 1/8″ of fabric edges

– Achieve professional piping by positioning the needle against the cord

Pro Tip: After zigzag testing, always return to straight stitch mode and reset the dial to “0” before storing your machine. Electronic models retain settings, but power surges can reset them unexpectedly.

Singer 3321 Mechanical Lever: Three-Position Adjustment Steps

The 3321’s metal positioning lever lives below the needle bar—look for the small tab marked with left/right arrows. This mechanical system offers ±1mm precision but requires manual resetting for each position change. Forget electronic memory; here, consistency comes from technique.

Lever Adjustment Without Causing Damage

1. Critical Safety Step

Unplug the machine. Mechanical levers require direct hand access near the needle assembly—live power risks accidental needle movement and injury.

2. Three-Position Control Sequence

– Left position: Push lever fully toward the machine’s left side (needle aligns with left presser foot edge)

– Center: Release lever to neutral position (needle pierces center of foot)

– Right position: Push lever toward machine’s right side (needle aligns with right foot edge)

3. The Handwheel Test for Accuracy

Lower the needle slowly using the handwheel while watching its path through scrap fabric. At right position, the needle should graze the right edge of the presser foot—any gap wider than a business card means you haven’t pushed the lever fully.

Sticking Lever Fixes That Prevent Costly Repairs

Stiff Lever Solution:

1. Remove the needle plate and clean lint from the lever base with a soft brush

2. Apply one drop of sewing machine oil to the lever pivot point

3. Work the lever back and forth 10 times to distribute oil

4. Test movement—should glide smoothly between positions

Warning: Never force the lever. If it won’t move after cleaning, internal components may be bent—seek professional service immediately. Forcing it causes gear damage requiring $100+ repairs.

Why Your Singer Needle Won’t Move Left (4432 Fix)

Electronic models like the 4432 commonly stick on left position due to thread jamming the width dial mechanism. This isn’t a software glitch—it’s preventable mechanical interference.

Step-by-Step Unjamming:

1. Turn machine off and unplug

2. Rotate stitch width dial slowly while watching the needle

3. If needle doesn’t move at “-1”, blow compressed air around the dial base

4. Select zigzag stitch at maximum width (+6) and rotate handwheel 5 times

5. Return to straight stitch and test left position again

When to Call a Technician: If the dial clicks but the needle stays centered, internal gears are stripped. This requires disassembly beyond user capabilities—don’t attempt DIY fixes.

Zipper Installation: Needle Position Secrets Pros Use

Forget special zipper feet—proper needle positioning solves 90% of zipper woes. These techniques work on both Singer models with zero extra tools.

Right-Side Zipper Technique

- Shift needle to extreme left position (4432: dial “-3”, 3321: lever left)

- Use the right edge of your standard presser foot as the guide against zipper teeth

- Maintain 1/8″ distance by keeping the foot edge flush with teeth

- Result: Zipper coils never catch the foot

Left-Side Zipper Method

- Move needle to extreme right position (4432: dial “+3”, 3321: lever right)

- Guide fabric using the left edge of the presser foot

- Stitch slowly—mechanical models may require micro-adjustments mid-zipper

Critical Mistake: Using center position for zippers. This forces you to “cheat” fabric alignment, causing wavy stitching. Always position the needle toward the zipper side you’re installing.

Topstitching Accuracy: Edge-Guided Techniques

Professional topstitching stays perfectly parallel to edges because they position the needle—not the fabric. Here’s how to replicate this on Singer machines.

1/16″ Topstitching on Medium Weights

- Needle position: Left (4432: “-1”, 3321: lever left)

- Guide method: Run fabric edge against right presser foot edge

- Why it works: Left needle shift creates consistent 1/16″ distance from edge

Parallel Decorative Lines Without Marking

- Stitch first line at center position

- Shift needle left 1 increment for second line

- Shift needle right 1 increment for third line

- Result: Three perfectly spaced lines (ideal for denim topstitching)

Pro Tip: Test on scrap first! On mechanical models, lever position may need slight adjustment based on fabric thickness.

Weekly Maintenance to Prevent Positioning Failures

Neglecting needle position controls causes 70% of alignment issues. This 5-minute weekly protocol keeps systems responsive.

Electronic Models (4432):

– Wipe stitch width dial with dry microfiber cloth

– Remove lint from dial crevices using a soft brush

– Never use liquids—moisture damages electronic sensors

Mechanical Models (3321):

– Clean lever base with compressed air

– Apply sewing machine oil only to lever pivot point

– Test all three positions after cleaning

Monthly Check: Rotate through all positions 5 times. If movement feels gritty, repeat cleaning. Smooth operation prevents positioning drift mid-stitch.

When to Seek Professional Singer Service

Some issues require expert intervention. Stop adjusting immediately if you notice:

– Grinding sounds during position changes (indicates gear damage)

– Zero needle movement despite control adjustments

– Visible cracks in lever or dial housing

Cost-Saving Tip: Most Singer dealers offer $25 “precision calibration” services. This checks needle bar alignment and resets positioning mechanisms—far cheaper than replacing stripped gears ($85+).

Mastering needle position adjustment turns your Singer into a precision instrument. On the 4432, electronic controls deliver lab-grade accuracy for micro-topstitching. The 3321’s mechanical lever offers tactile feedback perfect for vintage fabric work. Both systems achieve professional results when you position the needle—not the fabric—against your guide. Implement these model-specific fixes before your next project, and watch uneven seams and snagged zippers become relics of the past. For ongoing success, perform the weekly maintenance protocol and always verify position with the handwheel test on scrap fabric first. Your sewing accuracy will never drift again.