Your Kenmore sewing machine suddenly stops advancing fabric properly, leaving you with frustrating bunching, uneven stitches, or fabric that won’t move at all. If you’re searching for how to adjust feed dogs on Kenmore sewing machine, you’ve hit the heart of the problem. Those metal teeth beneath your presser foot—the feed dogs—are failing to grip and move your fabric correctly. Whether they’re stuck too low, won’t engage properly, or need repositioning for free-motion quilting, this guide delivers the exact model-specific solutions you need without confusing jargon or generic advice.

When feed dogs sit too low, your machine creates skipped stitches and fabric piles up like an accordion. When they’re too high, they can snag delicate fabrics or cause inconsistent feeding. The good news? Most Kenmore feed dog issues can be resolved in under 15 minutes with basic tools and the right approach. By the end of this guide, you’ll know precisely how to diagnose, adjust, and maintain your specific Kenmore model’s feed dogs for flawless stitching on every project.

Find Your Kenmore Model Number Before Adjusting

Locate Model Number on Machine Body

Check these four critical spots before attempting any feed dog adjustment on your Kenmore sewing machine. The front panel near the handwheel hides most model numbers on newer machines. Flip your machine over and inspect the base for older models where manufacturers stamped identification directly onto metal. Some Kenmore models tuck the number on the back panel, often near electrical components. Don’t overlook your accessory compartment—many users discover their model number stashed beneath the built-in storage tray. Without the exact model, you risk making improper adjustments that could damage internal mechanisms.

Decode Kenmore Model Prefixes Correctly

Understanding your Kenmore’s manufacturing origin prevents costly mistakes when adjusting feed dogs. Machines with 385.xxxxxx numbering were actually manufactured by Janome, meaning their feed dog mechanisms follow Japanese engineering principles rather than traditional Kenmore designs. Specific models like 16231, 365.16765, and 13453 (Ultra Stitch 8) each have unique adjustment procedures that won’t cross-apply. Always include the full model number when searching online manuals—omitting the 385 prefix for Janome-made models will lead you to incorrect instructions that could damage your machine’s feed dog assembly.

Kenmore 16231 Feed Dog Adjustment Steps

Raise Feed Dogs for Normal Sewing Operations

Follow these precise steps when your Kenmore 16231 feed dogs won’t engage properly for regular sewing. First, turn your handwheel toward you until the needle reaches its highest position—this creates clearance for mechanism movement. Push the feed dog control button to the left while simultaneously rotating the handwheel one full revolution in your direction. You should see the feed dogs rise above the needle plate surface by approximately 1-2mm. Test the adjustment by manually turning the handwheel while watching the feed dogs move in their characteristic up-down-forward-backward motion.

Lower Feed Dogs for Free-Motion Techniques

For successful free-motion quilting on your Kenmore 16231, push the same control button downward until it clicks into the lowered position. The feed dogs should disappear completely beneath the needle plate, creating a smooth surface for manual fabric manipulation. Before starting your quilting project, verify no feed dog teeth protrude by running your finger gently across the plate surface. If you feel any metal teeth, the mechanism hasn’t fully disengaged, which will cause inconsistent fabric movement during free-motion work.

Fix Kenmore 365.16765 Low Feed Dog Issues

Diagnose Insufficient Feed Dog Height

When your Kenmore 365.16765 feed dogs won’t rise fully despite the lever being in “high” position, check these three critical points. First, confirm the external lever clicks positively into place—many users mistake partial engagement for full activation. Next, remove the needle plate using a small screwdriver and inspect for an internal height adjustment screw, typically located near the feed dog linkage. Finally, verify the entire feed dog assembly hasn’t shifted position in its mounting channel, which commonly happens after vigorous free-motion sewing sessions. This model’s unique dual-lever system often requires simultaneous adjustment of both mechanisms.

Perform Precise Height Calibration

Adjust your Kenmore 365.16765 feed dog height with this professional technique. With the needle plate removed, locate the small brass adjustment screw beneath the feed dog assembly. Using a precision screwdriver, turn the screw clockwise in quarter-turn increments to raise the feed dogs. After each adjustment, replace the needle plate and test the height by placing a business card under the presser foot—properly adjusted feed dogs should move the card smoothly when you turn the handwheel. Never force the screw beyond resistance, as this can damage delicate internal gears controlling your feed dog movement.

Solve Ultra Stitch 8 (13453) Feed Movement Problems

Troubleshoot Feed Dogs That Raise But Don’t Advance

When your Kenmore Ultra Stitch 8 feed dogs elevate but fail to pull fabric forward, execute this four-point diagnostic. First, remove the needle plate and bobbin case to expose the feed dog mechanism completely. Second, manually rotate the handwheel while observing the feed dog movement pattern—they should move in a distinct elliptical motion, not just up and down. Third, check for thread nests or lint buildup jamming the linkage points where feed dogs connect to drive mechanisms. Fourth, inspect the timing belt for proper tension; a loose belt causes feed dogs to lose forward momentum despite correct height positioning.

Restore Proper Feed Dog Motion Pattern

Fix inconsistent fabric feeding on your Kenmore 13453 with this sequence. Power off and unplug your machine, then remove all thread from the system. With the needle plate off, apply one drop of sewing machine oil to each feed dog pivot point using an eyedropper for precision. Manually work the feed dogs through their full range of motion for 30 seconds to distribute lubrication. Reassemble the machine and test on scrap fabric using a straight stitch at medium speed. The fabric should advance smoothly without requiring manual pulling—if not, internal gear misalignment likely requires professional service.

Universal Feed Dog Maintenance Protocol

Perform Weekly Preventive Cleaning

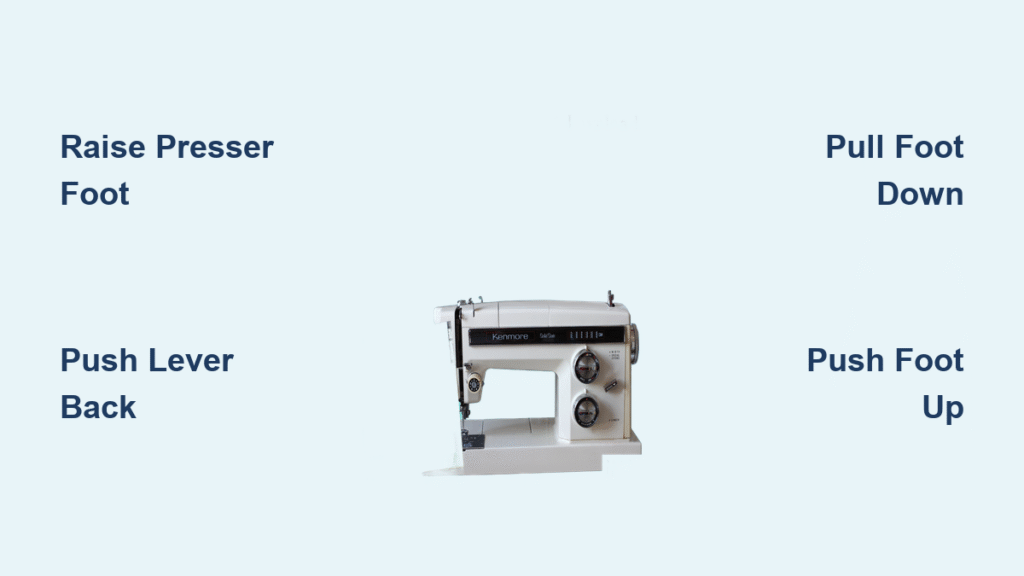

Prevent 90% of Kenmore feed dog issues with this 5-minute weekly routine. After unplugging your machine, raise the presser foot and remove the needle plate screws. Lift off the plate and use a small, stiff brush (included with most Kenmore models) to dislodge lint from around the feed dogs. Follow with short bursts of compressed air to remove stubborn debris from linkage points. Reinstall the plate and test feed dog movement by manually turning the handwheel—clean mechanisms should operate with smooth, quiet motion. Neglecting this simple step causes most “feed dogs won’t raise” complaints among Kenmore users.

Identify When Professional Service Is Needed

Know these four red flags indicating your Kenmore feed dog problem requires expert attention. Visible wear on feed dog teeth—especially flattened or broken serrations—means replacement is necessary. Grinding or clicking noises during operation signal internal gear damage beyond user adjustment capabilities. If feed dogs move inconsistently (sometimes working, sometimes not), internal timing issues likely exist. Complete failure to engage despite correct lever position often indicates broken linkage components requiring disassembly skills beyond typical home maintenance. Don’t force mechanisms when these signs appear—further damage increases repair costs significantly.

Model-Specific Feed Dog Adjustment Resources

Access Official Kenmore Manuals Online

Retrieve precise feed dog adjustment instructions for your exact Kenmore model in four steps. Visit sears.com and navigate to the “Manage My Life” section, then select “Manuals.” Enter your complete model number, remembering to add the 385 prefix for Janome-manufactured machines (e.g., 385.16231 instead of just 16231). Download the full manual and search for “feed dog adjustment” or “feed mechanism” in the index. These official documents contain exploded diagrams showing internal components specific to your model—critical when attempting feed dog height calibration beyond basic lever operation.

Match Feed Dog Position to Your Project Type

Optimize your Kenmore sewing results by aligning feed dog position with fabric characteristics. For standard woven fabrics, keep feed dogs at standard height with lever fully engaged. When working with delicate silks or sheers, lower feed dogs slightly using internal adjustment screws to reduce fabric distortion. Heavy denim or canvas often benefits from raising feed dogs 0.5mm higher than normal to ensure positive fabric grip. Free-motion quilting demands complete disengagement—verify no teeth protrude above the needle plate before beginning decorative stitching. Always test adjustments on fabric scraps matching your project material before committing to final seams.

Your Kenmore’s feed dogs should create consistent, even fabric movement when properly adjusted—no manual pulling required. Test all adjustments on scrap fabric first, especially when working with specialty materials. Establish a weekly cleaning habit to prevent most feed dog issues before they start. When in doubt about internal mechanisms, consult your model-specific manual or contact an authorized Kenmore service center rather than risking further damage. With these precise adjustment techniques, you’ll transform frustrating sewing sessions into smooth, professional-quality results on every project.