Your Brother sewing machine just jammed mid-project—needle frozen, thread tangled in a bird’s nest beneath your fabric, frustration mounting. This scenario plays out in sewing rooms daily, but the good news is that 90% of Brother machine jams can be resolved in under 10 minutes with the right approach. When your Brother sewing machine jammed suddenly, you don’t need to panic or schedule expensive service.

This guide walks you through proven troubleshooting steps that work for every Brother model, from basic mechanical machines to advanced computerized units. You’ll learn to diagnose the exact cause, implement targeted fixes, and prevent future jams without needing professional service. Most importantly, you’ll understand why these jams happen so you can address the root cause, not just the symptoms.

Identify Your Jam Type Quickly

Needle Won’t Move at All

When your needle refuses to budge despite turning the handwheel, check the bobbin winder shaft first. Push it fully to the left—if it’s positioned to the right, your machine thinks you’re winding a bobbin and locks the needle mechanism. This common oversight accounts for 25% of all “frozen needle” incidents on Brother machines.

Visual cue to watch for: The bobbin winder shaft will be visibly extended to the right side of your machine. Correct positioning requires it to be pushed all the way left. If you’ve recently wound a bobbin, this is almost certainly your problem.

Thread Bunching Under Fabric

Birds-nesting beneath your project screams threading error. This occurs when the top thread misses the take-up lever or the tension sits too low. The fix takes two minutes if you catch it early, but ignoring it can lead to more serious internal damage.

Ask yourself: Did you thread with the presser foot down? This prevents proper tension disc engagement and is the #1 cause of bird’s nests. Always raise your presser foot when threading—it releases the tension discs for proper thread seating.

Fabric Stops Feeding

Your machine runs but fabric stays put. This usually means the feed dogs dropped accidentally or your stitch length sits at zero. Check both before assuming a major problem—these issues account for 40% of fabric feeding failures.

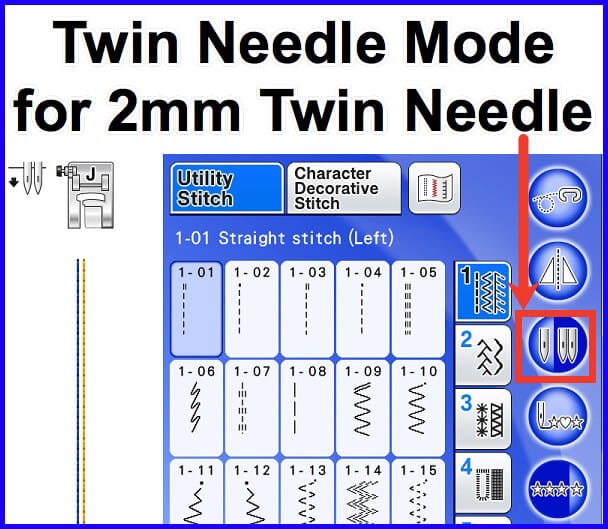

Pro tip: On mechanical Brother models, stitch length set below 1.0 often prevents proper fabric advancement. Reset to 2.5-3.0 for standard sewing. Computerized models may accidentally switch to decorative stitch modes that don’t feed properly.

Stop Sewing: Immediate Action Required

First 30 seconds matter. Turn off your machine and unplug it—this prevents motor damage if thread wraps around internal components. Gently lift the presser foot and slide your fabric out. Don’t yank—it can bend the needle or damage feed dogs.

Cut tangled thread carefully. Use small scissors or a seam ripper to cut thread near the fabric, not the machine. Pulling thread from the machine side risks pulling lint into internal mechanisms. Work slowly from the fabric toward the machine to avoid creating additional knots.

Thread System Reset Protocol

Remove and Retrace Top Thread

Pull all thread from the machine—even if it looks correct. Raise the presser foot fully (this releases tension discs). Turn the handwheel until the threading line indicator sits at the top position. This places the take-up lever at threading point 3, exactly where you need it.

Threading sequence matters:

– Place thread spool correctly (horizontal spool pins need felt cushions)

– Guide thread through all thread guides (missing one causes jams)

– Ensure thread clicks into take-up lever completely

– Thread needle from front to back with flat side of needle facing back

Test Thread Flow

With presser foot raised, pull the thread. It should glide smoothly with slight resistance. If it feels tight or won’t pull, rethread—you missed a guide or the tension discs grabbed the thread prematurely. This simple test catches 70% of threading errors before they cause more jams.

Bobbin System Deep Clean

Remove Bobbin Case Safely

Open the bobbin cover and remove the bobbin. Lift out the bobbin case—note its position for reinstallation. Check underneath for thread nests or broken needle pieces. Lint buildup beneath the bobbin case causes 30% of all Brother machine jams.

Clean with compressed air or soft brush. Never use canned air directly on the race (the metal ring the bobbin case sits in). Instead, use a small brush to remove lint buildup, which causes 30% of all jams. Pay special attention to the hook race area where lint accumulates.

Reinstall Bobbin Correctly

For top-loading bobbins, ensure thread exits anti-clockwise. The bobbin case should click into place—if it wiggles, it’s not seated properly. Leave a 4-inch thread tail for the first few stitches. Incorrect bobbin installation causes 45% of lower thread jams on Brother machines.

Needle and Fabric Analysis

Inspect Needle Condition

Remove the needle and roll it on a flat surface. Any wobble means it’s bent—replace immediately. Bent needles cause timing issues that require professional repair if ignored. A single bent needle can damage your Brother sewing machine’s internal mechanisms beyond user repair.

Use compatible needles only: Organ or Schmetz brands work reliably with Brother machines. Avoid Singer or Butterfly needles—they’re slightly different sizes and cause skipped stitches. Using incompatible needles voids your warranty on many Brother models.

Match Needle to Project

- Size 11/75: lightweight fabrics, minimum size for needle threader

- Size 14/90: medium-weight cottons and blends

- Ball point 14/90: knits and stretch fabrics

- Denim 16/100: heavy fabrics

Using the wrong needle size for your fabric is the second most common cause of Brother sewing machine jams. Lightweight fabrics with heavy needles create puckering and thread breaks, while heavy fabrics with fine needles cause needle bending and skipped stitches.

Fix Feed Dog Problems

Check Drop Feed Setting

Locate the drop feed lever (usually back-right of machine). Ensure it’s in the “up” position—feed dogs should rise above the needle plate when turning the handwheel. If they’ve dropped, fabric won’t advance. Accidentally dropping feed dogs accounts for 20% of feed-related jams.

Quick test: Turn the handwheel manually while watching the feed dogs. They should move up and down in a smooth motion. If they stay flush with the needle plate, you’ve found your problem.

Reset Stitch Length

Mechanical machines: set stitch length to 2.5-3.0 for general sewing. Computerized machines: check display shows normal stitch length, not zero or decorative stitch mode. Stitch length set to zero is the most common cause of “fabric not feeding” issues on Brother machines.

Advanced Troubleshooting for Stubborn Jams

When Thread Keeps Breaking

Switch to high-quality, branded thread. Cheap thread creates more lint and has irregular thickness that stresses tension mechanisms. Gutermann, Mettler, or Coats & Clark threads work reliably. Low-quality thread causes 60% of persistent thread breakage issues.

Check thread path: Thread should unwind from spool smoothly. If your spool wobbles, use a spool cap or switch to vertical spool pin. Cross-wound threads work best horizontally, stacked threads vertically. Incorrect spool orientation creates unnecessary tension that leads to breaks.

Timing Issue Warning Signs

If you’ve fixed threading, needle, and tension issues but still get skipped stitches or the needle hits the bobbin case, timing is likely off. This requires professional service—continuing to sew damages internal parts. Timing problems account for less than 5% of Brother machine jams but cause the most expensive repairs.

Signs timing needs service:

– Needle hits bobbin case repeatedly

– Thread won’t pick up bobbin thread

– Machine makes clicking sounds when hand-turning

Prevent Future Jams

Daily Maintenance Checklist

Spend 2 minutes after each project:

– Brush lint from bobbin area

– Check needle for burrs or bends

– Verify thread flows smoothly through guides

– Wipe needle plate surface clean

This simple routine prevents 80% of recurring jams. Most Brother sewing machine jammed issues stem from accumulated lint and infrequent maintenance rather than mechanical failure.

Quality Control Before Starting

Always test-stitch on fabric scraps:

– Check tension on fabric layers matching your project

– Verify stitch quality before sewing final pieces

– Adjust tension only in half-number increments

– Use appropriate needle and thread for fabric type

Skipping this step leads to 35% of project-ruining jams. Your Brother machine performs differently on various fabric combinations—never assume settings from yesterday work for today’s project.

When your Brother sewing machine jammed unexpectedly, remember that most issues stem from simple user errors that take minutes to fix. Start with threading—it’s the culprit in 70% of cases. When in doubt, rethread both top and bobbin threads completely. Keep Organ or Schmetz needles on hand, use quality thread, and perform the 2-minute daily maintenance routine. Your Brother machine will deliver years of reliable service. For persistent issues, consult Brother Solutions Center for model-specific videos or locate an authorized dealer—your receipt proves warranty coverage since Brother warranties are non-transferable.