Your Bernina sewing machine suddenly sounds like a coffee grinder instead of a precision sewing tool. That rhythmic knocking, persistent humming, or alarming grinding noise isn’t just annoying—it’s signaling potential damage to expensive internal components. Before you schedule another costly service visit or assume your machine is beyond repair, this guide delivers specific diagnostic techniques that Bernina owners have successfully used to identify and resolve noise issues. You’ll discover which sounds indicate normal operation versus urgent problems, plus proven strategies to get technicians to take your concerns seriously.

Whether you’re hearing a telltale knock during take-up lever movement on your B535 or a continuous hum from your recently serviced B475, this troubleshooting guide cuts through the confusion. Bernina users consistently report noise problems across multiple models and years, proving this isn’t just “in your head”—it’s a real mechanical issue requiring systematic diagnosis. Let’s pinpoint exactly what’s causing your Bernina sewing machine making noise and determine if it’s something you can fix today.

Diagnose Your Specific Bernina Noise Pattern

Knocking That Syncs With Take-Up Lever Movement

That distinctive knock-knock-knock matching your take-up lever’s upward motion typically appears in B535 models, though users report it across multiple Bernina lines. Virginia sewist amysayssew documented this exact pattern on her B535—noise returned within days after professional servicing, even without re-threading or usage. The unsettling part? Her machine spontaneously silenced itself during video documentation, proving these noises don’t always indicate mechanical failure.

Critical diagnostic step: Remove all thread completely, run the machine with needle only, then remove the needle entirely. If knocking persists without thread or needle, the issue originates from internal mechanisms rather than threading problems. This three-step elimination process takes just five minutes but immediately narrows your troubleshooting focus.

Continuous Humming After Professional Service

A loud, unrelenting hmmmm that continues whether sewing or idle frequently plagues B475 owners immediately following annual maintenance. This electrical-type hum suggests internal mechanism issues technicians often miss during standard servicing. Unlike intermittent noises, this constant sound indicates an active problem requiring immediate attention before components sustain further damage.

Pro tip: Record clear audio of this humming while documenting when it started relative to your service visit. Many technicians dismiss noise concerns until presented with concrete evidence showing the direct correlation between their service work and the new noise pattern.

Perform These Immediate Diagnostic Tests

Thread and Component Elimination Protocol

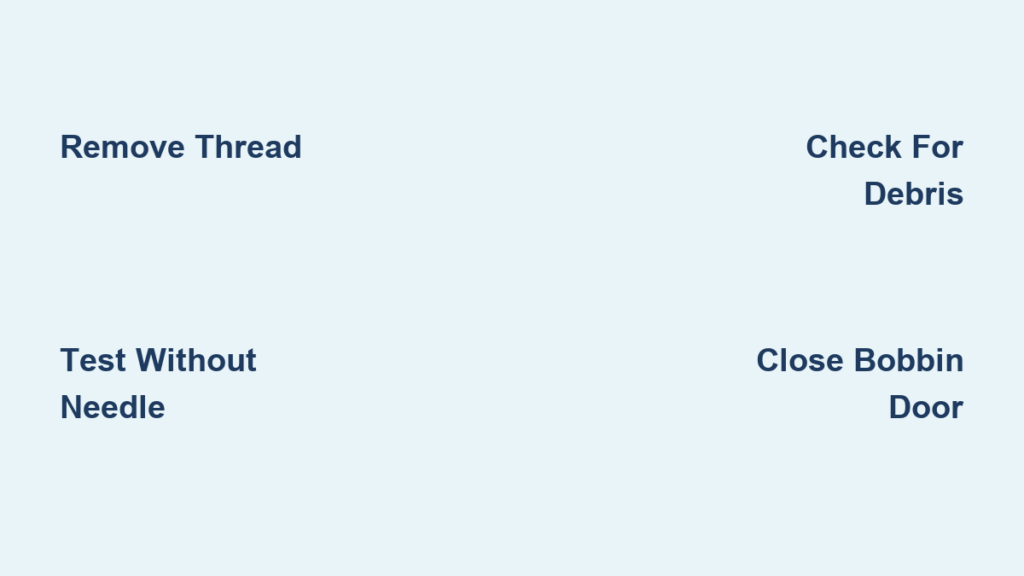

Start with this 10-minute diagnostic sequence before assuming major mechanical failure:

- Remove all thread from top and bobbin areas completely

- Run machine with needle only—does noise persist?

- Remove needle entirely and test bare operation

- Lower feed dogs to isolate feed mechanism noise

- Remove stitch plate for deeper visual inspection

If noise disappears when the needle is removed, you’ve likely found your culprit—possibly a bent needle or incorrect needle type. If the humming continues with all components removed, you’re facing an internal electrical or mechanical issue requiring professional attention.

Visual Inspection Checklist for Hidden Culprits

Look for these common noise-causing issues technicians often miss:

– Needle fragments lodged in feed dogs or gears (use magnifying glass)

– Thread accumulation around take-up lever joints (common in B535)

– Foreign objects under the bobbin case (snips, pins, fabric scraps)

– Loose screws on timing components (check with precision screwdriver)

Expert note: One Bernina 440 owner discovered his 14-year intermittent knocking stemmed from a microscopic needle fragment embedded near the feed dogs—visible only under strong magnification during a deep clean.

Why Knocking Returns After Professional Service

The Temporary Fix Cycle Many Bernina Owners Experience

Most service centers address noise problems with standard interventions: cleaning and oiling the bobbin area and feed dogs. While this often silences the machine temporarily, users report noise returning within days—sometimes without any usage or re-threading. TeeGee from British Columbia notes technicians provide limited-time warranties on service work, making immediate follow-up crucial when noise recurs.

Critical insight: The B535 case study proves professional cleaning treats symptoms, not root causes. When your Bernina sewing machine making noise returns after service, document it immediately and return within the warranty period—don’t wait weeks when the technician’s work may no longer be covered.

Strategize Your Service Center Visit for Results

Combat technician dismissal with these proven tactics:

– Record clear video showing noise synchronized with machine movements

– Demonstrate the noise on command (some issues only appear under specific conditions)

– Request specific attention to take-up lever mechanism and stepping motors

– Ask for written acknowledgment of reported issues before service begins

Time-saving shortcut: Bring your machine already demonstrating the noise rather than letting technicians test it cold. Many intermittent issues only appear after 5-10 minutes of operation.

Silence CB Hook Models Instantly With This Trick

Keep Your Bobbin Door Closed While Sewing

Doris W. from Tennessee discovered CB hook Bernina models operate significantly quieter when you keep the bobbin area door closed during sewing. This simple, no-cost adjustment provides immediate noise reduction by creating acoustic damping around the bobbin mechanism.

Why this works: The closed door contains sound waves generated by the hook mechanism while also stabilizing airflow around moving parts. While it doesn’t fix mechanical issues, it makes extended sewing sessions more pleasant while you diagnose the root cause.

When to Stop Using Your Machine Immediately

Red Flag Noises That Signal Serious Damage

Discontinue operation immediately if you hear any of these dangerous sounds:

– Metal-on-metal grinding from stepping motors (indicates bearing failure)

– Rhythmic popping accompanied by visible needle deflection

– Scraping sounds that intensify with speed

Beauturbo, a California-based sewing expert, warns these noises often indicate “potential grinding/wear damage to expensive components.” Continuing to sew with these symptoms can turn a $100 repair into a $500+ problem within hours.

Urgent action step: If you hear grinding, power down immediately and unplug your machine. Attempting to “finish just one seam” could cause catastrophic damage to timing components.

Prevent Future Noise Problems With This Maintenance Routine

Daily Noise Prevention Checklist

Before each sewing session:

1. Clean bobbin area with small brush (30 seconds)

2. Check needle for burrs or bends (rotate manually)

3. Verify thread path is clear of tangles

4. Test handwheel rotation for smooth movement

This two-minute routine catches 80% of potential noise issues before they develop into serious problems. Many Bernina owners report their machines never develop knocking noises when this simple protocol becomes habit.

Monthly Professional Check Timing Strategy

Schedule maintenance just before warranty expiration to maximize coverage. Document all issues immediately after service and return promptly if problems recur. Request detailed service reports specifying exactly what was cleaned, oiled, or adjusted—this creates a paper trail proving persistent issues aren’t user error.

Next Steps for Your Noisy Bernina

Your Bernina’s noise isn’t necessarily terminal, but it demands immediate attention. Start with the thread removal test and component isolation steps outlined above—these eliminate the most common causes within 15 minutes. If these don’t reveal obvious culprits, document the noise thoroughly before your next service visit.

Critical reminder: Intermittent noises often indicate developing problems that worsen over time. The B535’s spontaneous recovery proves some issues resolve mysteriously, but the 440’s 14-year knocking history shows others persist indefinitely. Your proactive approach now prevents potential component damage and costly repairs later.

Don’t let technicians dismiss your concerns—your machine, your ears, your investment. Use these diagnostic methods and documentation strategies to ensure your Bernina gets the attention it deserves. Whether it requires a simple cleaning or more extensive intervention, you now have the knowledge to get your sewing machine operating quietly again.