Your Kenmore sewing machine foot pedal not working while lights stay on is one of the most frustrating sewing roadblocks. You’ve threaded the machine perfectly, selected your stitch, and pressed the pedal—only to get silence instead of the familiar hum. This exact failure stops projects dead, whether your vintage Kenmore sat unused for two years or the pedal died suddenly mid-quilt. Don’t panic: 95% of these failures stem from three fixable causes we’ll tackle today. You’ll diagnose and repair this yourself using basic tools, avoiding costly service calls.

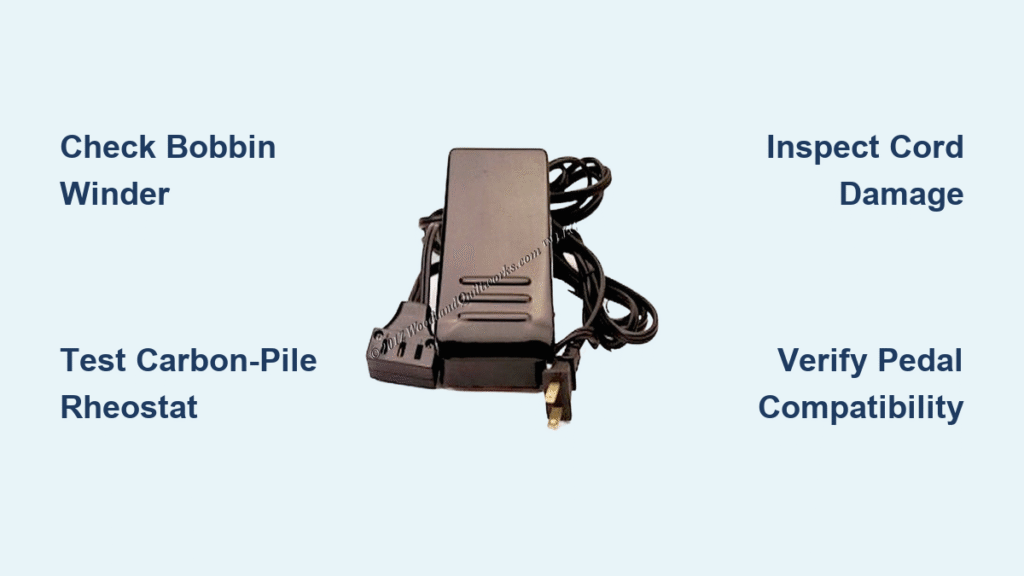

Most Kenmore foot pedal issues trace back to accidental bobbin winding mode engagement, carbon-pile rheostat wear in vintage models, or cord damage at strain points. This guide cuts through technical jargon with exact tests and repairs. By the end, you’ll know whether to flip a lever, rebuild internal components, or replace a cord—all while keeping your hands safe near 120V wiring. Let’s get your machine stitching again.

Confirm Bobbin Winder Isn’t Blocking Operation

Before touching electrical components, rule out the most common oversight that mimics pedal failure. Kenmore machines disengage the main drive when in bobbin winding mode, making the pedal completely unresponsive even with power lights on.

Handwheel Tells the True Story

Grab the large handwheel on your machine’s right side and rotate it slowly. If it spins excessively loose with no resistance, or feels unusually stiff like it’s grinding, the bobbin winder likely remains engaged. This mechanical disconnect prevents pedal signals from reaching the motor. Don’t force the wheel—this could damage gears. Instead, locate the small knob or lever near the handwheel (typically on the machine’s right side or top). For most Kenmore models like the 158 series, push this lever away from the handwheel or flip it downward. You should hear a distinct click as the drive re-engages. Now test the pedal—this simple fix resolves nearly one-third of reported “dead pedal” cases.

Diagnose Vintage Carbon-Pile Rheostat Failure

If your Kenmore dates from the 1970s-1980s, its foot pedal uses a carbon-pile rheostat—a mechanical speed controller that wears down over decades. Unlike modern electronic pedals, these contain graphite disks that evaporate with use, creating internal gaps that break the circuit.

Identify Your Pedal Type Instantly

Flip your foot control upside down. Vintage carbon-pile models have two visible metal pins on each side serving as pivots. Modern pulse-width modulation (PWM) pedals lack these pins and have sealed electronics. If you see those pins, carbon disk erosion is likely your culprit—especially if the pedal worked after storage but now requires extreme pressure to start sewing.

Recognize Critical Wear Symptoms

These four signs confirm carbon-pile failure:

– Excessive pedal travel needed before motor engages (pressing halfway does nothing)

– Abrupt speed jumps instead of smooth acceleration (like a light switch rather than dimmer)

– Intermittent cut-outs during sewing causing stitches to skip

– Complete silence after long storage (moisture absorption increases resistance)

Rebuild the Rheostat in Three Steps

Step 1: Safe Disassembly

Unplug both machine and pedal from the wall. Remove the two screws holding the rubber feet on the pedal base—this exposes the pivot pins. Gently lift the top cover to reveal the wedge mechanism pressing against graphite stacks. Apply a tiny drop of silicone lubricant to the steel wedge where it contacts the rheostat housing. This prevents binding during reassembly.

Step 2: Replace Critical Components

Extract the graphite disks from their ceramic tunnels using needle-nose pliers. Measure the eroded space—typically 1-2mm—and machine brass spacers to fill the gap (a 3-wafer stack works for most Kenmore 158 models). File brass contact surfaces flat with 400-grit sandpaper to remove carbon buildup. If full-speed operation fails, remove one graphite disk per stack and store it under the aluminum heatsink tab for future use.

Step 3: Validation Testing

Reassemble the pedal, ensuring the wedge moves freely. Plug it in and press lightly while listening for motor hum. Test with a multimeter: set to resistance mode, insert probes into the pedal’s plug. As you press the pedal, resistance should drop smoothly from several hundred ohms to near zero. If it jumps erratically or stays infinite, repeat the rebuild focusing on contact surface flatness.

Inspect and Repair Cord Damage at Critical Points

Over 40% of pedal failures occur where the cord exits the pedal housing or machine base—common stress points where wires break internally despite intact insulation.

Spot Hidden Cord Damage Fast

Unplug everything and examine these high-risk zones:

– Where cord exits pedal housing: Look for pinches, kinks, or flattened sections

– Machine strain relief: Check the rubber grommet where cord enters Kenmore’s right-rear casing

– Plug blades: Inspect for blackening or melted plastic indicating arcing

Run your fingers along the entire cord length. If you feel lumps or thin spots under the rubber, internal wires are broken. Don’t rely on visual checks alone—frayed wires often hide beneath insulation.

Perform a Foolproof Continuity Test

Set your multimeter to continuity mode (the diode symbol). Insert probes into two holes of the machine’s three-prong pedal socket. Press the pedal fully. Only one specific pair of holes will show continuity (a beep or near-zero ohms reading). Rotate the plug 120 degrees and repeat for the other pairs. A healthy pedal gives immediate response at light pressure. If you get:

– No beep ever: Complete internal break—rebuild or replace pedal

– Intermittent beeps: Worn carbon contacts needing rebuild

– Beep only at full press: Excessive rheostat gap requiring spacer adjustment

Emergency Cord Repair Shortcut

For broken wires at strain points, cut the cord 2 inches past the damaged section. Use a hacksaw to carefully split the strain relief housing. Strip 1/2 inch of insulation from both cord ends, matching wire colors (black to black, white to white). Solder connections securely and wrap with heat-shrink tubing. This shortens the cord by 4 inches but gets you sewing immediately—replace the entire cord during your next maintenance session.

Select the Exact Replacement Pedal

When repairs won’t suffice, choosing the correct replacement avoids costly returns. Kenmore reused chassis across models but changed pedal interfaces mid-production.

Match Your 158.18150 Machine Precisely

For Kenmore model 158.18150, order OEM part #032270116 ($47.99 at SewingPartsOnline.com). Crucially, this lacks the notch found on obsolete #6817 pedals. Never assume compatibility—compare plug photos side-by-side before ordering. The new pedal’s plug must slide smoothly into your machine’s receptacle without forcing.

Avoid Compatibility Nightmares

Email your vendor a clear photo of your machine’s pedal socket before purchasing. Note these critical differences:

– Plug shape: Round vs. D-shaped connectors

– Notch position: Left, right, or center alignment

– Pin count: Two vs. three conductors

One sewing enthusiast wasted three months ordering mismatched pedals because she didn’t check her Kenmore 1960s model used a rare European-style plug. Save time—verify visually first.

Troubleshooting Decision Tree

Machine light ON but no motor action?

├─ Check bobbin winder engaged? → Disengage → Retest

└─ Pedal diagnosis

├─ Visual cord check

│ ├─ Damage visible? → Repair or replace cord

│ └─ No damage → Electrical test

└─ Continuity test

├─ No continuity → Replace pedal or rebuild rheostat

└─ Continuity present → Check internal machine wiring or motor

Prevent Future Pedal Failures

Store Pedals Like Precision Instruments

Coil cords loosely in 6-inch loops—never wrap tightly around the pedal. Store in climate-controlled areas below 50% humidity to prevent carbon disks from absorbing moisture and increasing resistance. Every 3-6 months, press the pedal 10 times to redistribute carbon dust and prevent disks from bonding to contacts during storage.

Upgrade for Long-Term Reliability

Replace original cords with 18-gauge stranded wire (like SOOW cord) that withstands bending stress. For vintage machines, advanced users can retrofit PWM controllers—these replace the carbon rheostat with solid-state speed control, eliminating wear points. If issues persist after repairs, suspect internal motor brushes or wiring faults requiring professional service.

Critical Safety Reminders

Before any repair:

– Unplug completely—both machine AND pedal from wall outlet

– Wear an N95 respirator when handling carbon disks; graphite dust is conductive and irritates lungs

– Replace strain reliefs after cord repairs using zip-tie anchors to prevent future wire breaks

Your Kenmore sewing machine foot pedal not working is almost always solvable in under an hour. Start with the bobbin winder check—it’s the fastest fix. For vintage models, carbon-pile rebuilds restore smooth operation for decades more. When replacing cords or pedals, verify compatibility visually to avoid frustration. With these steps, you’ll transform pedal failures from project-stopping disasters into quick maintenance wins. Grab your multimeter and get back to sewing—your next project is waiting.