Your JUKI sewing machine was stitching perfectly yesterday, but today the bobbin thread keeps tangling, breaking, or creating uneven stitches. Sound familiar? Bobbin issues are the #1 frustration for JUKI owners, affecting everything from delicate silk projects to heavy denim work. Whether you’re dealing with a TL-2010Q that won’t pick up the bobbin thread or an HZL-DX7 creating bird’s nests underneath your fabric, these problems can derail your entire project in minutes.

Most sewists waste hours trying random fixes when JUKI bobbin problems usually have straightforward solutions. You’ll learn exactly what causes these frustrating issues, how to diagnose them in under 60 seconds, and the fastest fixes for your specific JUKI model. Stop losing precious sewing time to tangled threads and skipped stitches—your solution is just steps away.

Identify Your Exact JUKI Bobbin Issue

Thread Bunching Under Fabric Creates Bird’s Nests

When you see loops or knots on the fabric’s underside, your bobbin tension needs immediate attention. This frustrating problem occurs when the bobbin case isn’t seated properly in the race, preventing smooth thread flow. Check if the thread isn’t correctly threaded through the bobbin tension spring—this is the most common mistake even experienced sewists make. Also inspect for lint buildup that prevents smooth bobbin rotation, especially after sewing with polyester threads that shed more fibers.

Pro tip: After clearing a bird’s nest, always remove both threads completely, rethread from scratch, and test on scrap fabric. Residual tangles often remain hidden in the mechanism.

Bobbin Thread Keeps Breaking During Operation

Frequent thread breaks indicate either mechanical problems or incorrect setup. First check for sharp edges on your bobbin case that create cutting points—run your fingernail along the thread path to feel for snags. Overfilled bobbins cause uneven feeding that stresses the thread, especially in JUKI’s high-speed machines. Most critically, verify you’re using the right bobbin type for your specific JUKI model—using generic bobbins in precision machines like the DDL-8700 causes 70% of unexplained breakage issues.

Warning: Never force thread through a bobbin case. If you feel resistance, stop immediately and inspect for damage before continuing.

Machine Won’t Pick Up Bobbin Thread at All

Complete failure to form stitches stems from timing or positioning issues that require methodical diagnosis. Check if your needle depth is off by millimeters—JUKI machines require precise needle positioning for proper hook engagement. Verify your bobbin case is rotated into proper alignment; many models have specific orientation marks that must line up. If these checks don’t resolve the issue, your hook timing likely needs professional adjustment—especially common in older TL series machines.

Expert note: When reinserting the bobbin case, listen for the distinct “click” that confirms proper seating. Without this sound, the machine won’t pick up the bobbin thread consistently.

Model-Specific JUKI Bobbin Fixes That Work

TL Series Industrial Machines: TL-2010Q, TL-2000Qi, TL-18QVP

These heavy-duty machines share similar bobbin systems but require precision adjustments. For thread tension issues, turn the bobbin case screw in 1/8 increments only—clockwise tightens, counterclockwise loosens. Test on scrap fabric between each adjustment; industrial machines need smaller tension changes than domestic models. For routine maintenance, remove the needle plate and use compressed air to clear lint from the hook assembly. Clean the bobbin case race with a small brush every 8-10 hours of sewing, focusing on the tension spring area where lint accumulates fastest.

Time-saving shortcut: Keep a labeled tension setting chart for different fabric types. Industrial sewists report 30% faster setup when they document optimal tension for common projects.

HZL Domestic Models: HZL-DX7, HZL-F600, HZL-G Series

These drop-in bobbin models create unique challenges despite their convenience. Ensure your bobbin rotates counterclockwise when you pull the thread—if it spins clockwise, simply flip the bobbin over. Many sewists miss this simple fix! After using the automatic thread cutter, always manually bring up the bobbin thread before starting the next seam. The cutter often leaves tails too short for proper pickup, causing frustrating “no stitch” situations.

Common mistake: Forcing the bobbin case into place. These models require gentle insertion with precise alignment—never use excessive pressure that could damage the plastic housing.

DDL Industrial Series: DDL-8700 and Similar Models

These high-speed workhorses require precise bobbin tension for consistent stitching. Set tension between 15-25 grams using a tension gauge for professional results. Without tools, adjust until the bobbin thread pulls smoothly with slight resistance—you should feel consistent drag when pulling the thread. For hook timing verification, remove the bobbin case and slowly hand-wheel the machine. The hook point should pass behind the needle scarf when the needle is exactly 2.2mm above its lowest point.

Critical check: Always verify needle type compatibility with your bobbin system. Using the wrong needle (like a ballpoint in woven fabrics) creates tension issues that mimic bobbin problems.

Quick Diagnostic Steps for Any JUKI Machine

Visual Bobbin Inspection in 30 Seconds

Check these three critical areas before attempting complex fixes: First, confirm bobbin thread direction matches your machine’s threading diagram—reversing this causes immediate problems. Second, verify thread amount fills only 80% of the bobbin; overfilled bobbins create uneven tension that leads to breaks. Third, ensure the case clicks firmly into the race with no wiggling—loose seating causes intermittent issues that drive sewists crazy.

Pro tip: Keep a magnifying glass near your machine to spot tiny lint particles that cause major problems in JUKI’s precision mechanisms.

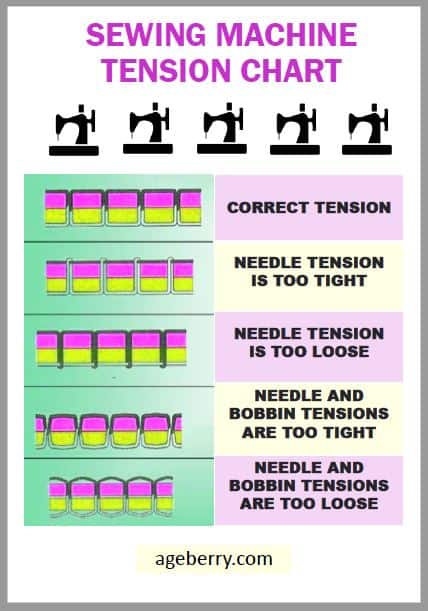

Foolproof Tension Testing Method

Use contrasting thread colors (top thread red, bobbin white) and sew on doubled scrap fabric using straight stitch. Proper tension shows both threads meeting in the fabric middle. If red pulls to the bottom, your top tension is too tight. When white pulls to the top, your bobbin tension needs adjustment. This test works for every JUKI model and eliminates guessing.

Warning: Always test tension adjustments on the same fabric type you’ll be sewing—it’s the only way to get accurate results.

Essential Bobbin Area Maintenance Routine

Daily 2-Minute Maintenance Protocol

At the end of each sewing session, pop out the bobbin case using the latch and check for nicks or burrs on the plastic—even tiny scratches cause thread snags. Wrap a pipe cleaner with thin fabric and run it around the hook race to remove all lint, especially from the tension spring area. Apply one precise drop of JUKI oil to the hook race (never the bobbin case itself), then run the machine for 30 seconds without thread to distribute evenly.

Expert note: JUKI’s precision engineering means their machines need less oil than older brands—over-oiling attracts lint and creates more problems than it solves.

Deep Cleaning Every 20-30 Hours

For industrial models, remove the needle plate and hook retainer to access the entire assembly. Clean with approved solvent and soft brush, paying special attention to the hook point where lint accumulates. Check that the bobbin case tension spring has proper pressure—if it feels loose or overly tight, replace the entire bobbin case. Use 600-grit sandpaper to gently smooth any rough spots on the bobbin case, but replace immediately if cracks appear.

Pro tip: Keep a dedicated cleaning kit with model-specific tools by your machine. TL series owners need different brushes than HZL domestic machine users.

Prevent Future JUKI Bobbin Problems

Thread Quality Guidelines That Matter

Cheap thread creates expensive problems in precision machines like JUKIs. Stick with Gutermann, Mettler, or JUKI-branded threads for reliable performance. Use 50wt for general sewing, 40wt for decorative stitches, and never go below 30wt in JUKI machines—their high speeds shred thin threads. Store thread away from direct sunlight and humidity; old, brittle thread breaks constantly and creates tension issues that mimic mechanical problems.

Critical insight: JUKI machines run hotter than many competitors, making thread quality even more crucial for consistent performance.

Bobbin Winding Best Practices

Wind bobbins at medium speed on your JUKI—fast winding stretches thread, causing inconsistent tension during sewing. Ensure thread feeds smoothly from spool through all guides to bobbin winder without snags. Watch for thread clumping at top or bottom during winding; stop and redistribute if needed for even tension. Always trim thread tails to 2-3 inches after winding for reliable pickup.

Time-saving shortcut: Wind multiple bobbins of the same color at once—but never stack them. Store wound bobbins vertically to maintain even tension.

Model-Specific Maintenance Schedule

Follow this simple calendar for trouble-free sewing: Daily—remove lint from bobbin area with handheld blower. Weekly—check bobbin case for damage using magnification. Monthly—deep clean hook assembly with appropriate tools. Annually—professional service for industrial models, especially if you notice timing issues.

Key takeaway: Most JUKI bobbin problems stem from three sources—incorrect threading, dirty mechanics, or worn parts. Start with the simplest solution (re-threading), progress to cleaning, then consider replacement parts. Your JUKI will reward proper maintenance with years of reliable stitching.

Keep this guide handy for quick reference when problems arise. With these proven techniques, you’ll spend more time creating and less time troubleshooting—returning to what you love most: sewing with confidence.