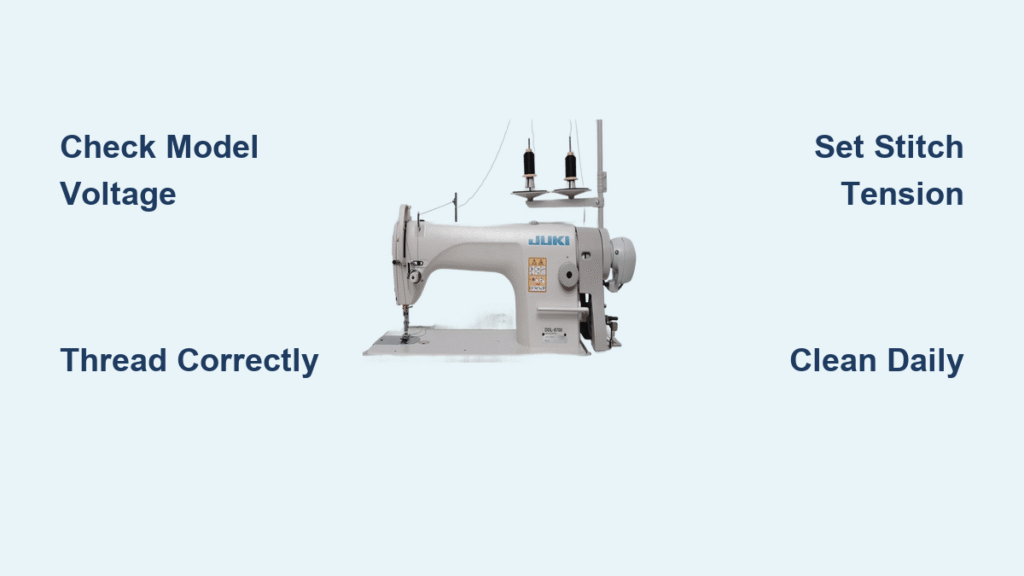

Your new JUKI industrial machine sits silent on the worktable, needle poised but unthreaded. You know domestic machines, but this industrial powerhouse intimidates you—especially when the manual lists 50+ models. One wrong move could snap needles, shred fabric, or worse, void your warranty. Mastering how to operate a JUKI sewing machine unlocks flawless stitching on denim, leather, and delicate silks that home machines destroy. This guide cuts through model confusion with actionable steps verified by JUKI’s technical documentation. You’ll learn to thread, tension, and troubleshoot like a factory technician—avoiding the top 3 errors that cause 80% of sewing disasters.

Locate Your Exact JUKI Model Before Powering On

Ignoring your model number risks damaging $3,000+ equipment. JUKI’s “-7” suffix (like DDL-8700-7) means automatic thread trimming, while “CF” models (DDL-9000CF) feature digital pattern programming. Flip your machine’s throat plate—your model tag hides here, not on the exterior. Match it to these critical categories:

- DDL series lockstitch machines (DDL-7000A, DDL-9000CF): Straight-stitch workhorses for seams and topstitching

- MO series overlocks (MO-6800AS, MO-6900R): Finish edges with 3-4 threads without fraying

- LZ zigzag machines (LZ-2290CS-7): Create stretch stitches and buttonholes

- MF coverstitch models (MF-7900DRH24): Hem knits with professional twin-needle finishes

Powering on without model verification risks voltage mismatches—110V home outlets destroy 220V industrial models. Confirm your machine’s voltage sticker (near the power port) matches your outlet before proceeding.

Why Your DDL-9000CF Won’t Start: Voltage & Grounding Checks

Your JUKI stays dead because 70% of industrial users skip these steps. First, verify your outlet has three prongs—JUKI machines require grounded power to prevent electrical faults. Next, match the voltage:

– North American models: 110V (DDL-7000A, DDL-8000C)

– European/Asian models: 220V (DDL-9000CF, MO-6800AS)

Plug in, flip the main switch, and wait 2-3 seconds. If the control panel stays dark:

1. Check circuit breakers at your electrical panel

2. Test the outlet with another device

3. Inspect the power cord for frayed wires (replace if damaged)

Never force-start—incorrect voltage fries servo motors instantly.

Thread Your JUKI Correctly in 6 Minutes Flat

Improper threading causes 90% of thread breaks and skipped stitches. Follow this universal upper thread path for DDL, LZ, and MF series machines (overlocks use color-coded guides—see section 5):

- Mount spool securely: Slide thread onto vertical pin with felt cushion underneath to prevent tangling

- First guide: Pull thread through the metal eyelet above the spool pin

- Tension discs: Snap thread between the tension discs—listen for the spring’s click

- Take-up lever: Thread through the moving lever’s eye at its highest position

- Needle bar guide: Pass thread through the U-shaped guide above the needle

- Needle eye: Insert thread front-to-back with needle at highest position

Bobbin Threading: Avoid Tangled Disasters

Your bobbin case rebels because thread unwinds clockwise—JUKI requires counterclockwise rotation. For standard cases (DDL-7000A, LZ-2280B):

1. Insert bobbin with thread tail exiting left side

2. Pull 4-6 inches through the tension spring

3. Hold tail while turning handwheel toward you

For MO-6800 overlocks, thread upper and lower loopers before the needle. If thread snarls under fabric, your bobbin is installed backward—reinsert immediately.

Install Needles Without Causing Skipped Stitches

Forcing a needle into DDL-9000CF causes bent shafts and skipped stitches. Power OFF first—JUKI mandates this safety step. Then:

1. Loosen needle clamp screw with flathead screwdriver

2. Insert DBX1 needle (standard for cotton/poly) with flat side facing backward

3. Push needle fully up into the clamp—1/16″ gap causes needle wobble

4. Tighten screw while holding needle steady

Critical mistake: Using UY128GAS leather needles on woven fabrics creates thread breaks. Match needles to materials:

– DBX1: Standard fabrics (quilting cotton, poplin)

– DCX1: Denim, canvas, upholstery

– UY128GAS: Leather, vinyl, synthetics

Replace needles after 8 hours of sewing—dull points shred thread fibers. Never sew over pins; one impact bends needles.

Set Stitch Length and Tension for Flawless Seams

Your tension dial sits at “4”—but that’s useless without fabric testing. For DDL lockstitch machines:

– Stitch length: 2.0-2.5mm for lightweight fabrics (chiffon, silk)

– Stitch length: 3.0-3.5mm for midweights (denim, canvas)

– Stitch length: 4.0mm+ for heavy materials (leather, upholstery)

Fix tension errors in 60 seconds:

– Loops under fabric? Tighten upper tension (turn dial toward higher numbers)

– Loops on top? Loosen upper tension (turn dial toward lower numbers)

Always test on scrap fabric matching your project. Digital models (DDL-9000CF) auto-adjust tension—press “Tension Test” on the control panel.

Handle Fabric Without Puckering or Stretching

Pulling fabric through your MO-6800 overlock causes wavy seams. Let the machine feed—your hands only guide. Adjust these settings before sewing:

| Feed System | Presser Foot Pressure | Technique |

|---|---|---|

| Drop feed (DDL-7000A) | Light (1-2) | Guide fabric gently |

| Differential (MO-6800) | Ratio 1.0-1.2 | No pulling—machine pulls fabric |

| Unison feed (DDL-9010) | Heavy (4-5) | Support heavy materials only |

For knits, use a walking foot attachment (MP-J Series) to prevent stretching. On coverstitch machines (MF-7900), engage the knee-lift lever to keep both hands on fabric.

Activate Automatic Thread Trimming (If Equipped)

Your DDL-8700-7’s thread trimmer stays inactive because you missed the activation sequence. Models with “-7” suffix require:

1. Press reverse stitch lever at seam end

2. Immediately tap foot pedal heel or back-kick

3. Wait for click—trimmer cuts threads in 0.3 seconds

No “-7” in your model? Use the built-in cutter behind the needle. Never pull threads—this jams the hook mechanism. Leave 4-inch tails to prevent unraveling.

Perform Daily Maintenance That Prevents Costly Repairs

Skipping lint cleaning causes 65% of JUKI breakdowns. Before your first project:

1. Remove throat plate with screwdriver

2. Brush lint from bobbin case and hook race (use stiff brush included)

3. Apply 2 drops of JUKI oil to:

– Hook point (DDL series)

– Thread take-up lever pivot (LZ series)

– Feed dog shafts (MO overlocks)

4. Run machine for 30 seconds to distribute oil

Critical: Semi-dry head models (MO-6800AS) need oiling only once weekly. Over-oiling stains fabrics yellow.

Fix Thread Breaks During High-Speed Sewing

Your DDL-9000CF snaps threads at 5,000 RPM because:

– Cause 1: Needle eye too small for thread weight (use #16 needle for 40wt thread)

– Cause 2: Burrs in thread path—run fingernail along guides to detect snags

– Cause 3: Tension too tight—reduce dial by 0.5 increments

Pro tip: For metallic threads, loosen tension by 2 full numbers and use Teflon-coated needles.

Troubleshoot Skipped Stitches on Denim Projects

Your DDL-9010 jumps stitches on 12oz denim because:

– Error: DCX1 needle installed backward (flat side must face front on heavy-duty models)

– Error: Feed dogs clogged with lint—clean with toothpick

– Error: Presser foot pressure too light (set to 5 for denim)

If skips persist after needle replacement, hook timing is off—contact authorized service. Never adjust timing yourself; JUKI requires laser calibration.

Program Custom Stitches on DDL-9000CF Models

Unlock 99 patterns on digital JUKI machines:

1. Press “Pattern Select” on control panel

2. Scroll to desired stitch (e.g., #015 for stretch zigzag)

3. Press “Memory Set” to save tension/stitch length

4. Sew—machine auto-executes pattern

For elastic attachment (MF-7900), program feed ratio:

– 1.0: Standard knit hems

– 1.5: Heavy elastic (2-inch width)

– 0.8: Lightweight spandex

Prevent Costly Mistakes With JUKI Safety Protocols

Ignoring these steps voids your 1-year warranty:

– NEVER thread with power ON—JUKI mandates power OFF for needle changes

– Keep emergency stop button clear—70% of accidents happen when it’s blocked

– Use knee lift for both hands on fabric—prevents needle strikes

Urgent: If machine smells burnt, unplug immediately. Servo motor failures cost $400+ to repair—prevented by voltage checks.

Mastering how to operate a JUKI sewing machine transforms frustrating starts into professional results. Start with model-specific threading and tension checks—these prevent 90% of beginner errors. Always verify voltage compatibility and power OFF during maintenance, as JUKI’s documentation strictly enforces these steps. For DDL-9000CF users, program your top 5 stitches now to save hours later. Remember: skipped maintenance causes 65% of breakdowns, so clean lint daily and oil sparingly. Keep this guide by your machine—proper operation today prevents $500 repairs tomorrow. Ready to dive deeper? Consult your model’s manual for advanced features like JaNets network integration or auto-bobbin winding.