Your Bernina 930 abruptly stopped mid-stitch, emitting a burning smell that sent panic through your sewing session. When your prized machine starts smoking or seizing, knowing how to take apart a Bernina sewing machine becomes critical to diagnose motor failures, belt issues, or electrical faults. Unlike generic sewing machines, Bernina models like the 930 feature unique internal mechanisms that demand precise disassembly techniques. This guide cuts through the confusion with model-specific steps for removing your Bernina 930’s top cover—the gateway to inspecting 90% of common malfunctions. You’ll learn to navigate hidden fasteners, avoid costly reassembly errors, and safely investigate smoke sources without voiding your warranty.

Skipping proper disassembly risks snapped clips, misplaced screws, or electrical damage that turns a simple fix into an expensive repair bill. By following this Bernina 930-specific process, you’ll gain controlled access to the motor, belt, and circuitry while preserving all delicate components. Whether you’re troubleshooting sudden shutdowns or performing preventative maintenance, these steps apply to most Bernina mechanical models from the 1980s-1990s era. Let’s dive into the exact sequence that professionals use to open your machine without damage.

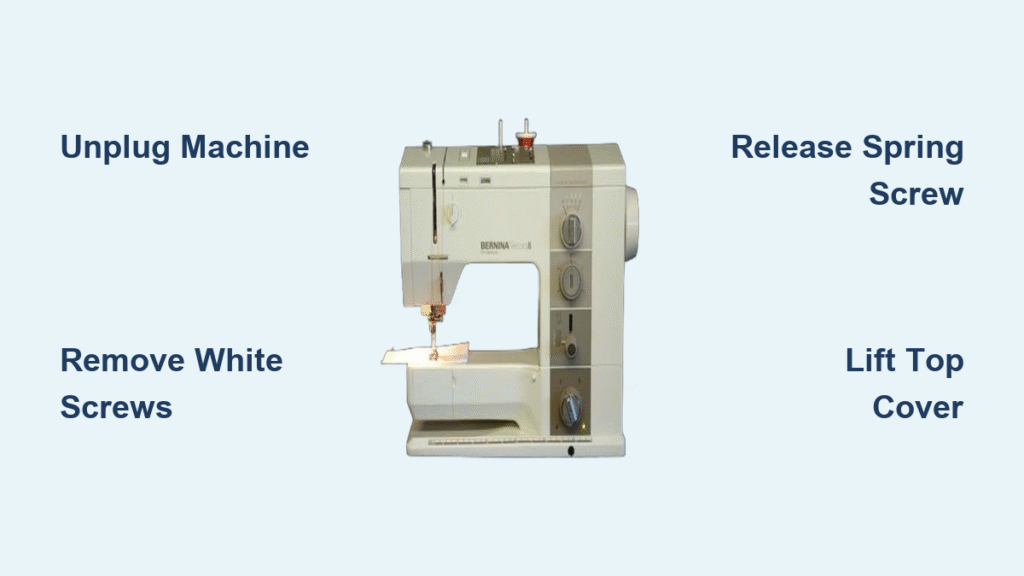

Remove Top Cover Safely

Power Down and Prepare Workspace

Unplug your Bernina 930 immediately—never skip this step when smoke or electrical issues occur. Remove the needle and presser foot to eliminate puncture hazards, then clear your workspace of thread scraps and fabric that could interfere with screws. Lay out a soft towel to protect the machine’s surface, and place a magnetic tray nearby for screws. Crucially, take detailed photos of the machine’s top and interior from multiple angles before touching a single fastener. These visual references prevent reassembly nightmares when you encounter Bernina’s non-intuitive clip placements.

Identify All Fastening Points

Your Bernina 930 uses three critical fastening points for top cover removal, all cleverly concealed:

– Two white plastic screws hidden beneath the bobbin winder lid (easily mistaken for decorative elements)

– One spring-loaded metal screw near the machine’s center that rotates but doesn’t fully detach

– Four to six plastic clips along the rear housing that require strategic release

Do not force any components—Bernina’s engineering relies on precise pressure points. If a fastener resists, double-check for hidden latches before applying torque. The white plastic screws are model-specific; losing or damaging them complicates reassembly since standard replacements won’t fit Bernina’s proprietary threading.

Access Bobbin Winder Compartment

Open the Hidden Lid

Locate the small rectangular lid on the top right housing—this covers the bobbin winder mechanism. Gently lift the lid upward using your thumbnail in the seam; it pivots on a rear hinge. If it sticks, check for thread snags around the edges (a common culprit in seized mechanisms). Never pry aggressively—Bernina’s plastic housings crack easily under pressure. Once open, you’ll see the two white plastic screws securing the top cover. Note the lid’s spring tension; it snaps shut when released, so keep a finger on it during disassembly.

Remove White Plastic Screws

Using a #1 Phillips screwdriver, turn both white plastic screws counterclockwise until fully removed. These screws are shorter and finer-threaded than standard hardware—overtightening during reassembly strips their delicate heads. Place them in a labeled container immediately; mixing them with metal screws causes alignment issues. As you lift each screw, observe the rubber gaskets beneath—they prevent dust ingress and must be reinstalled flat to avoid cover gaps. If screws feel gritty, clean them with a dry cloth before storage; lint buildup indicates poor maintenance contributing to your smoke issue.

Handle the Stubborn Metal Screw

Understanding the Spring-Loaded Design

The central metal screw isn’t a fastener—it’s a locking pivot point with internal spring tension. Rotating it releases the top cover’s rear clips without removing the screw itself. Attempting full removal damages the spring mechanism, a costly error requiring Bernina-specific replacements. This component only turns 90-120 degrees clockwise or counterclockwise; forcing beyond this range snaps internal tabs. Apply downward pressure on the top cover while rotating—this compresses the spring to disengage the lock. If it won’t budge, your cover clips are still engaged elsewhere.

Release the Top Cover

Press firmly downward on the top cover near the metal screw while turning it counterclockwise in quarter-turn increments. You’ll feel subtle clicks as internal clips release. Stop immediately if resistance increases—Bernina’s plastic clips fracture under excessive force. Once all rear clips disengage (typically after 1-2 full rotations), the cover lifts 1-2mm. Do not pull upward yet; front clips remain engaged. This spring-loaded screw returns to its original position when released, so note its alignment for reassembly. If the cover feels loose but won’t lift, hidden front clips are still active—proceed to the next step.

Lift and Remove Top Cover

Check for Hidden Clips

After addressing visible fasteners, gently rock the top cover side-to-side while lifting from the rear. Bernina 930 models have 2-3 spring clips along the front edge near the needle plate. Use a plastic spudger (or flathead screwdriver wrapped in electrical tape) to depress these clips inward while lifting. Never insert metal tools directly—they scratch housing surfaces and cause permanent cosmetic damage. If clips resist, check for thread jamming in the needle bar area; this often binds the cover during smoke-related failures.

Document Everything

As the cover lifts, photograph cable routing to the motor and circuit board—Bernina’s wiring harnesses follow specific paths. Note the belt’s tension and alignment on the motor pulley; a misrouted belt causes smoke through friction. Inspect for:

– Lint accumulation around motor vents (a primary smoke trigger)

– Discolored components indicating electrical arcing

– Belt positioning relative to the handwheel

– Screw hole patterns for reassembly alignment

Store the cover upside-down on a soft surface to avoid damaging internal connections.

Inspect for Smoke Sources

Motor and Belt Area

With the cover off, focus on the motor assembly directly beneath the handwheel. Check for blackened motor windings—a telltale sign of electrical overload. Examine the drive belt for melting or fraying; a seized bearing overheats the belt, creating smoke. Verify proper belt tension: it should deflect 3-5mm when pressed midway. If lint packs the motor vents (common in neglected machines), use a soft brush—not compressed air—to avoid pushing debris deeper.

Electrical Component Check

Trace wiring from the motor to the circuit board, looking for:

– Burnt traces (brown/black streaks on green boards)

– Melted wire insulation near solder points

– Corroded terminals from humidity exposure

– Loose connectors causing intermittent arcing

Never touch components while the machine is plugged in. If you spot charring on the circuit board, stop—this requires professional repair. Most smoke issues stem from mechanical failures (belt/motor), not electronics.

Common Disassembly Mistakes

Forcing the Metal Screw

The #1 error is treating the spring-loaded screw like a standard fastener. Excessive rotation strips the internal cam, turning a 10-minute fix into a $150 repair. Remember: press down while turning, and stop at the first sign of resistance. If the cover won’t release, hidden front clips—not the metal screw—are likely the culprit.

Skipping Documentation

Bernina 930s have asymmetrical cable routing and clip placements. Assuming “it’ll fit back” guarantees misalignment. Photograph every angle, especially wire paths over the bobbin case. One misplaced cable rubs against moving parts during operation, causing new failures.

Prepare for Deeper Access

Pressure Foot Mechanism Removal

For issues beyond the top cover (e.g., tension problems), remove the needle plate to access pressure foot screws. However, 85% of smoke cases are resolved with top cover access alone—avoid deeper disassembly unless necessary. If proceeding, photograph the tension disc assembly; reassembling it incorrectly causes thread breaks.

Belt Tension Adjustment

Before full disassembly, check belt tension through the top opening. A loose belt slips and overheats; an overtightened one strains the motor. The ideal tension allows 3-5mm deflection. Adjust via the motor mount screws—loosen to decrease tension, tighten to increase.

Reassembly Best Practices

Organize Your Screws

Use a segmented tray labeled “Bobbin Lid,” “Top Cover,” and “Internal.” The white plastic screws are 3mm shorter than internal metal screws—mixing them causes stripped threads. Reinstall them finger-tight first, then snug with 1/4-turn increments to avoid cracking the housing.

Test Before Full Assembly

After repairs, reposition the top cover loosely and plug in the machine. Test at low speed while monitoring for smoke or unusual sounds. Only secure all fasteners once operations are smooth. If issues persist, the cover provides instant access—no re-disassembly needed.

Safety Reminders

Never reassemble while plugged in—residual current can arc through exposed components. If smoke occurred, allow 2+ hours for the motor to cool completely. For severe electrical damage (burnt smell, visible charring), consult a certified Bernina technician; DIY repairs risk fire hazards. Always wear safety glasses when handling internal parts—metal fragments from stripped screws cause eye injuries.

Key Takeaway: Successfully taking apart your Bernina 930 hinges on mastering three elements: the hidden bobbin winder screws, the spring-loaded metal pivot point, and meticulous documentation. Start by unplugging the machine and photographing every angle before removing the two white plastic screws under the bobbin lid. When tackling the central metal screw, remember to press down while rotating—it releases clips but doesn’t fully remove. Most smoke issues trace back to lint-clogged motor vents or a misaligned drive belt, both visible once the top cover lifts. Avoid the critical mistakes of forcing fasteners or skipping photo documentation, and always test functions with the cover loosely positioned before final reassembly. For persistent electrical issues, professional help beats safety risks—your Bernina’s precision engineering deserves expert care.