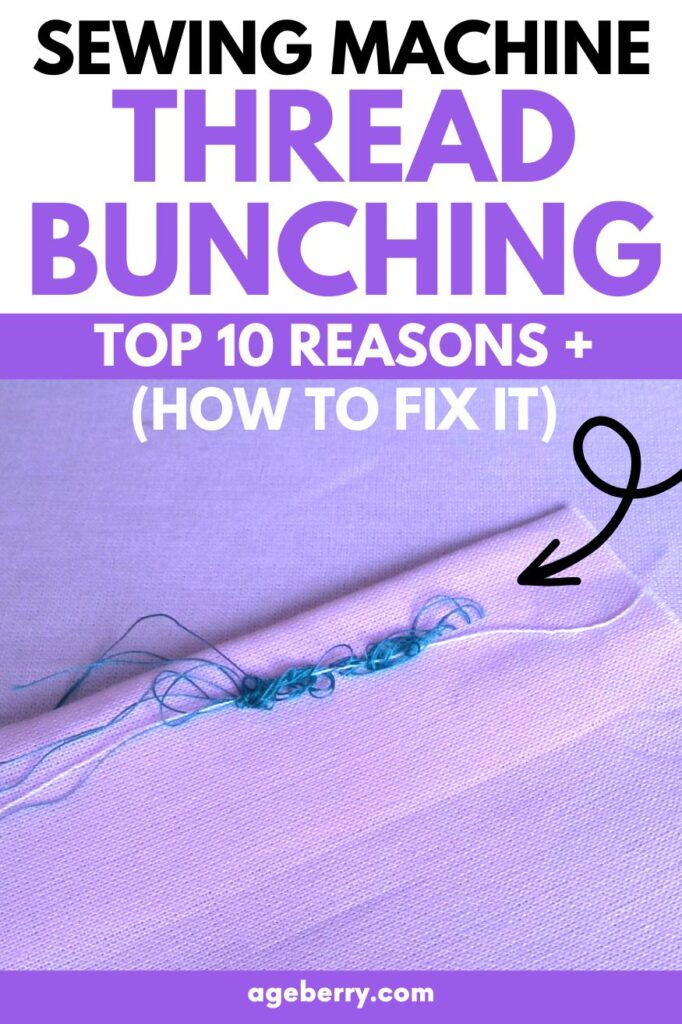

Thread bunching transforms your sewing session from creative joy to frustrating chaos in seconds. That familiar “bird’s nest” of tangled thread under your fabric locks your Singer machine, ruins projects, and makes you question your sewing skills. The truth? Most Singer thread bunching issues stem from just a few common problems you can diagnose and fix yourself in under 10 minutes—no professional help required. This guide reveals exactly why your Singer creates those annoying tangles and delivers step-by-step solutions that work immediately.

When thread bunching strikes, you’ll typically find knotted messes either on top or underneath your fabric. These locations aren’t random—they’re critical clues that pinpoint exactly where to focus your troubleshooting efforts. By understanding what these visual indicators mean, you can skip hours of guesswork and go straight to the solution that will get you sewing smoothly again.

Pinpoint Where Your Thread Bunching Occurs

Top-Side Bunching Means Bobbin Area Problems

When you see tangled thread on top of your fabric, your instinct might tell you to check the upper thread path—but the real problem almost always lies in the bobbin area. This visual clue saves you from wasting time adjusting tension settings that aren’t causing your issue.

Bobbin Quick Check Procedure:

– Remove your bobbin case and hold the thread tail—does the bobbin lower slowly when you release it?

– If it drops straight to the floor, you’ve missed the tension spring during threading

– Examine thread flow—does it move smoothly with slight resistance when you tug it?

The drop test reveals everything about your bobbin tension. Properly threaded, your bobbin should descend slowly when you hold the thread horizontally. A free-falling bobbin means the thread isn’t engaging the tension mechanism correctly, creating perfect conditions for top-side bunching.

Bottom-Side Bunching Signals Upper Thread Issues

Contrary to what many sewers believe, thread tangles underneath your fabric rarely indicate bobbin problems. Instead, this location points directly to upper thread path issues—usually improper threading through the tension discs.

Upper Thread Path Diagnostic:

– Cut thread 3-4 inches from the spool and completely remove all upper thread

– Re-thread your Singer with the presser foot raised (critical step many miss)

– Lower the presser foot and gently pull the thread—you should feel significant resistance

Most bottom-side bunching happens because sewers thread their machines with the presser foot down. This prevents the thread from seating properly between the tension discs, allowing too much thread to feed through and create those frustrating knots underneath your fabric.

Immediate Diagnostic Tests

Perform the 30-Second Tension Balance Check

Before attempting complex fixes, verify your tension balance with this quick test:

1. Thread your machine with two different colored threads (one for top, one for bobbin)

2. Sew on doubled scrap fabric matching your project material

3. Examine both sides of the stitching

What Your Stitches Reveal:

– Top thread visible on bottom: Upper tension too loose or bobbin tension too tight

– Bobbin thread visible on top: Upper tension too tight or bobbin tension too loose

– Identical appearance on both sides: Perfect tension balance achieved

This visual test eliminates guesswork and tells you exactly which tension mechanism needs adjustment—saving you from making unnecessary changes that could create new problems.

Check Your Needle First—It Solves 40% of Issues

A bent or incorrect needle causes nearly half of all thread bunching problems. Remove your needle and place it on a flat surface—if it rocks or wobbles, it’s bent and needs immediate replacement.

Needle Selection Cheat Sheet:

– Light fabrics (chiffon, silk): Size 9-11 sharp needle

– Medium fabrics (cotton, linen): Size 12-14 universal needle

– Heavy fabrics (denim, canvas): Size 16-18 jeans needle

– Knits: Size 11 ballpoint needle

– Leather: Size 16 wedge point needle

Never pull fabric while sewing—that’s the #1 cause of bent needles. Let the feed dogs move the fabric for you to maintain needle integrity and prevent thread bunching.

Deep Clean Critical Areas

Bobbin Area Complete Cleaning Process

Lint and thread fragments accumulate rapidly in the bobbin area, creating the perfect conditions for thread bunching. This hidden buildup disrupts the delicate balance needed for smooth stitching.

Step-by-Step Bobbin Cleaning:

1. Remove the needle plate, bobbin, and bobbin case completely

2. Use a small brush or tweezers to extract all visible lint and thread pieces

3. Apply one drop of sewing machine oil to the shuttle center (the metal piece holding the bobbin)

4. Reassemble components and test sew on scrap fabric

Pro Tip: Clean your bobbin area after every 3-4 projects or whenever you notice thread starting to behave erratically. This simple habit prevents most recurring bunching issues.

Upper Thread Path Refresh Technique

Lint also builds up between the tension discs, preventing proper thread control. This hidden problem causes inconsistent tension and sudden bunching.

Upper Path Cleaning Method:

1. Unthread the machine completely

2. Raise the presser foot to open the tension discs

3. Fold a scrap of fabric into a narrow strip

4. Run it through the entire upper threading path

5. Pull the fabric back and forth gently to trap and remove hidden debris

This 60-second cleaning technique removes debris that hand brushing misses. Most sewers see immediate improvement in stitch quality after completing this simple procedure.

Fix Tension Disc Engagement Issues

Verify Tension Disc Functionality

Tension discs control resistance on your upper thread. When they fail to close properly, thread flows too freely, creating bunching underneath fabric.

Tension Disc Test:

1. Thread your machine normally

2. Raise the presser foot and pull thread—it should move easily

3. Lower the presser foot and pull thread—should feel significant resistance

4. If no resistance appears, discs aren’t engaging properly

Reset Tension to Factory Baseline

Most Singer machines operate best with upper tension set between 3-5 for standard sewing. Reset your tension dial to 4 as a starting point.

Tension Reset Process:

– Turn tension dial to highest number (usually 9)

– Turn back to 4, listening for each click

– Test sew on scrap fabric matching your project

– Adjust in tiny increments (½ number at a time)

Remember: tension adjustments are extremely sensitive. Never change tension by more than one full number between tests—small changes make dramatic differences in stitch quality.

Replace Worn Components

Inspect Bobbin Case for Damage

A damaged bobbin case creates snags that lead to persistent thread bunching. Remove your bobbin case and examine it under good light.

Critical Damage Indicators:

– Cracks anywhere on the case

– Rough or burred edges near the thread exit point

– Tension spring that feels loose or overly tight

– Visible grooves where thread has worn into the plastic

Replace the bobbin case immediately if you spot any damage. Aftermarket cases cost $10-15 but can solve stubborn bunching issues instantly.

Check Needle Plate for Burrs

The needle plate’s hole develops burrs after needle strikes, creating thread-shredding edges. Run your finger carefully around the needle hole—any rough spots indicate burrs.

Burr Detection Protocol:

– Use a magnifying glass to inspect the needle hole

– Look for shiny spots or rough edges

– Replace needle plate if any damage appears visible

Emergency Quick Fixes That Work Now

When standard troubleshooting doesn’t solve immediate bunching problems, try these rapid solutions:

30-Second Fixes That Solve 80% of Issues:

1. Change everything: Install new needle, new thread spool, new bobbin

2. Start fresh: Completely re-thread from scratch with presser foot raised

3. Hold steady: Gently hold thread tails for first 3-4 stitches

4. Speed adjustment: Sew slower until issue resolves

These combined actions solve persistent bunching issues when individual steps prove insufficient. Many sewers report immediate success with this four-step emergency protocol.

Prevent Future Thread Bunching

Establish Daily Prevention Habits

Simple daily practices prevent most thread bunching issues before they start.

Essential Daily Checklist:

– Start each project with a new needle (seriously—this makes a huge difference)

– Test tension on scrap fabric matching your project

– Clean bobbin area before starting new projects

– Hold thread tails for first 3-4 stitches when beginning new seams

Quality Thread Selection Guide

Thread quality directly impacts bunching frequency. Cheap threads create more lint, break easier, and have inconsistent diameter—all contributing to tension problems.

Recommended Thread Brands:

– Gutermann: Minimal lint, consistent diameter, strong construction

– Mettler: Smooth finish, excellent color selection

– Aurifil: Italian quality, virtually lint-free

– Robison Anton: Strong polyester, vibrant colors

Final Takeaway: Singer sewing machine thread bunching almost always stems from tension imbalance, but the location of the mess tells you exactly where to look. Top-side bunching equals bobbin problems; bottom-side bunching equals upper thread issues. Keep your machine clean, use quality thread and fresh needles, and establish simple maintenance habits to prevent these frustrating tangles from returning. When problems persist despite these fixes, professional service may address deeper mechanical issues beyond standard user maintenance—especially if you notice the needle hitting the bobbin case or failing to catch thread completely. Remember: consistent prevention takes less time than fixing a bird’s nest, so build these quick checks into your sewing routine for smooth, professional results every time.