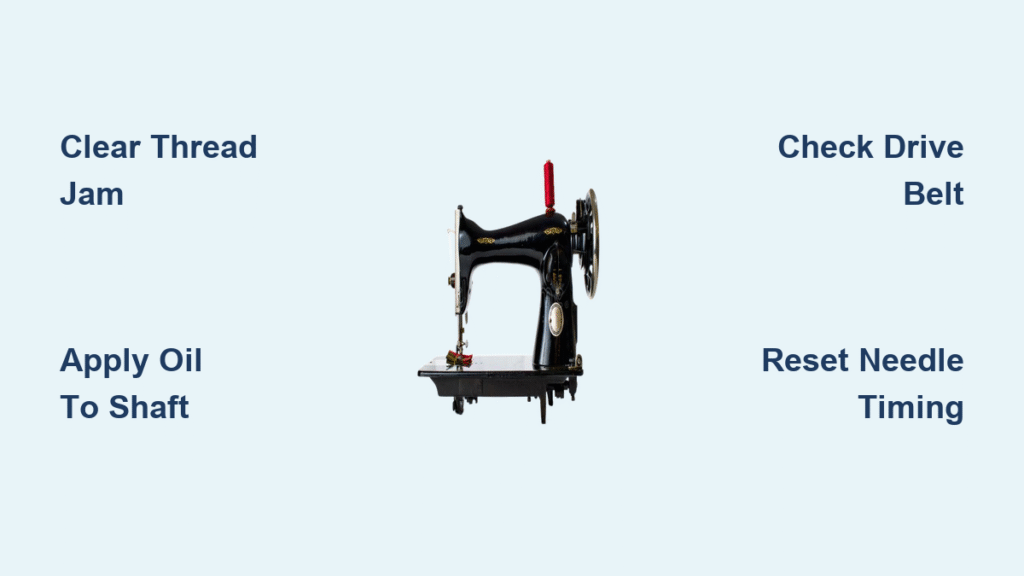

Your Singer sewing machine sits silent, the handwheel frozen solid under your fingers. You press gently, then harder—nothing moves. That sinking feeling hits: another project derailed by a locked handwheel. But before you call for repairs, know this: 95% of Singer handwheel lock-ups stem from thread jams, dried lubrication, or simple clutch issues you can fix yourself in under an hour. This guide delivers proven solutions for Singer Heavy Duty models 4411, 4423, 4432, and 4452—plus universal fixes for any Singer machine. Stop the frustration and get back to sewing today.

Why Your Singer Handwheel Locks After Storage (4423/4432 Models)

Singer Heavy Duty machines like the 4423 and 4432 frequently seize when stored for weeks or months. Bronze bushings dry out, causing metal-on-metal friction that grinds the handwheel to a halt. You’ll hear a metallic squeak during initial use, followed by complete lock-up as the shaft overheats. Don’t force it—this strips internal gears. Instead, apply targeted heat and oil to revive the mechanism.

Heat and Oil Revival Method for Dry Shafts

- Unplug the machine and remove the needle, bobbin, and presser foot

- Warm the machine with a hairdryer 6 inches away for 2-3 minutes (never use open flame)

- Apply one drop of synthetic sewing machine oil behind the face plate (top shaft) and under the bottom cover (bottom shaft bushing)

- Rock the handwheel 1/8 turn clockwise, then counter-clockwise—never force full rotation

- Repeat every 2 minutes for 15-30 minutes until movement returns

Pro Tip: Use a Zoom-Spout Oiler for precision. Standard droppers flood bearings—one drop per shaft is all you need.

Clear Thread Jams in Bobbin Case in 90 Seconds

Thread jams cause 70% of sudden handwheel lock-ups. The culprit? Bobbin thread wrapping twice around the hook race, creating a mechanical stranglehold. You’ll feel extreme stiffness or hear grinding when attempting to turn the wheel. Skip the panic—this fix takes two minutes.

Fastest Bobbin Jam Clearance Sequence

- Remove the needle plate with a Phillips #2 screwdriver

- Pop out the bobbin case and inspect the hook race for orange thread loops

- Use tweezers to unwind thread counter-clockwise (clockwise tightening worsens jams)

- Check feed dog area for felt padding debris from old bobbins

- Reassemble and test handwheel movement before reinstalling the needle

Warning: Never turn the handwheel with jammed thread present. This bends the hook assembly, requiring $40 part replacements.

Unlock a Seized Needle Bar Without Damage

When the needle bar won’t move vertically, rust on the vertical shaft is the likely villain. Common after humidity exposure, this causes complete handwheel lock-up with visible orange discoloration behind the face plate. Forcing movement cracks internal linkages—use this safe extraction method instead.

Rusty Needle Bar Rescue Protocol

- Remove needle and presser foot

- Locate Torx T15 set screws securing the needle bar behind the face plate

- Loosen screws 1/4 turn (do not remove completely)

- Place 6mm wooden dowel against the needle bar base

- Tap dowel lightly with a mallet—never strike metal directly

- Clean shaft with 600-grit wet/dry sandpaper until smooth

- Apply sewing oil before reassembly

Real Fix: A Singer 4432 owner freed a 5-year-seized bar in 12 minutes using this method—no parts replaced.

Diagnose Broken Drive Belts vs. Clutch Failures

Zero resistance when turning the handwheel? You’ve got a broken drive belt (Singer part #BL-1425 for 44-series). The wheel spins freely but the needle stays dead. Handwheel turns but needle doesn’t move? Your clutch knob is disengaged or stripped. Here’s how to tell:

Belt vs. Clutch Troubleshooting Flow

- Engage the clutch knob by pushing it firmly inward—you should hear a click

- If no click, replace the clutch collar (part #BL-3027)

- If wheel spins freely, inspect the belt path:

- Motor pulley → handwheel pulley → bobbin-winder pulley

- Look for cracks, stretching, or dislodgement

- Replace belts annually—rubber degrades even with light use

Critical: Never use automotive belts. Singer-specific #BL-1425 maintains exact tension for 44-series machines.

Reset Timing After Major Thread Jams

Severe jams often knock needle timing out of spec. You’ll notice the handwheel locks only at bottom dead center (needle’s lowest point). This happens when the needle bar shifts vertically during jam clearance. Fix it before sewing—misalignment breaks needles instantly.

44-Series Timing Calibration

- Remove needle plate to view hook assembly

- Turn handwheel slowly until needle reaches bottom dead center

- Verify hook tip passes 2mm behind needle eye (not above or below)

- Loosen Torx T15 set screws on vertical connecting rod

- Adjust needle bar height to 1.15 inches (29.2mm) from clamp to casting

- Retighten screws and test with handwheel rotation

Pro Tip: Mark original screw positions with nail polish before adjusting. Most timing errors come from over-correction.

Prevent Future Lock-Ups With 5-Minute Maintenance

80% of handwheel failures are preventable with routine care. Singer’s bronze bushings demand specific attention—standard sewing oil clogs mechanisms. Follow this maintenance schedule religiously:

Singer-Specific Maintenance Checklist

- After every project: Brush lint from bobbin race with soft brush

- Every 8-10 hours: Remove needle plate and use lint roller on feed dogs

- Every 20 hours: Apply one drop of Singer All-Purpose Oil to:

- Top shaft behind face plate

- Bottom shaft bushing under machine

- Needle bar guide bushing

- Annually: Replace drive belt and regrease gears with Tri-Flow Clear Synthetic Grease

Never use WD-40 or 3-in-1 oil—they attract lint and harden into gummy residue within weeks.

When to Call a Singer Repair Pro Immediately

Stop troubleshooting if you see metal shavings in oil ports or cracked gear teeth. These indicate catastrophic internal damage requiring factory-trained technicians. Also seek help for:

– Repeated jams after thorough cleaning (sign of worn hook assembly)

– Timing adjustments exceeding 1/16 inch (requires dial indicators)

– Grinding noises after lubrication (bearing replacement needed)

Red Flag: Forcing a locked handwheel to “break it loose” strips gear teeth. If resistance exceeds 2 pounds, stop immediately.

Don’t let a frozen handwheel derail your sewing projects. Start with the 30-second test: remove the needle, bobbin, and presser foot. If the wheel moves, you’ve got a thread jam—clear it in 90 seconds. If still locked, apply the heat-and-oil revival method for dry shafts. Keep your Singer humming with monthly oiling and post-project lint removal. Remember: never force the handwheel, always turn counter-clockwise, and use Singer-specific lubricants. With these fixes, your machine will outlast fast fashion—stitch by perfect stitch. Grab your Torx T15 screwdriver and get sewing again today.