Your Singer sewing machine has suddenly stopped working properly—the needle moves up and down, but the bobbin mechanism remains completely still. You’ve rethreaded everything twice, changed needles, and checked all the obvious issues, yet your Singer sewing machine bobbin not moving problem persists. This frustrating scenario affects countless sewers, especially owners of vintage models like the Singer Stylist Zig Zag 413 that rely on aging mechanical components. Understanding exactly why your bobbin stopped moving—and whether it’s a simple fix or requires professional attention—can save you hours of unnecessary troubleshooting and prevent costly repair mistakes.

When your Singer’s bobbin drive fails, you’ll typically see thread bunching underneath your fabric while the top thread appears normal. This happens because the stationary bobbin mechanism can’t interact with the moving needle thread. Let’s work through a systematic approach to diagnose and fix your Singer sewing machine bobbin not moving issue before you consider replacing your entire machine.

Spot Your Bobbin Movement Failure Immediately

Complete Cessation Symptoms

Remove your needle plate and manually rotate the handwheel toward you while watching the bobbin area. If the hook assembly shows absolutely zero movement while the needle bar cycles up and down, you’re dealing with mechanical failure rather than a simple threading problem. This is different from tension issues where the bobbin moves but doesn’t properly interlock threads.

Thread tangles under your fabric often accompany this failure, but don’t waste time adjusting tension settings. When your Singer sewing machine bobbin not moving problem involves complete mechanical failure, no amount of tension adjustment will solve the underlying issue. The key diagnostic test is simple: with the bobbin removed, does the hook assembly rotate when you turn the handwheel?

Hook Assembly Verification

Perform this critical test: watch the hook area closely while turning the handwheel after removing your bobbin case. The hook should rotate around the bobbin area. If it remains completely motionless—not even a slight twitch—you’ve confirmed true mechanical failure rather than a user error. Many sewers mistake this for a threading problem, but the absence of any hook movement indicates something more serious needs attention.

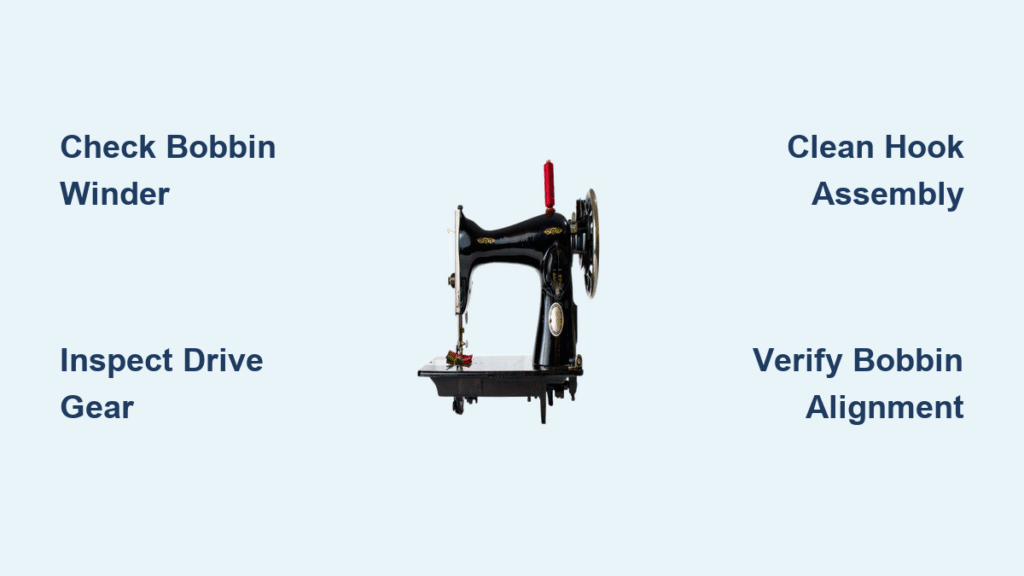

Broken Drive Gear Diagnosis

Access the Machine Base

Most vintage Singer bobbin movement failures trace back to a broken plastic drive gear. On models like the Singer Stylist Zig Zag 413, this gear connects the handwheel to the hook assembly. After decades of use, these plastic components naturally degrade and fail.

To inspect your drive gear:

1. Unplug your machine completely before proceeding

2. Remove the bottom cover (the actual machine base, not just the accessory tray)

3. Locate the plastic gear connected to the hook drive shaft

4. Examine carefully for cracks, missing teeth, or powdery plastic debris

If you find broken gear teeth or the gear spins freely on its shaft, your machine requires professional service. This repair involves complete disassembly and specialized parts that may no longer be available for vintage models.

Vintage Model Specifics

The Singer Stylist Zig Zag 413 commonly suffers this specific failure due to its plastic internal components. Users consistently report the bobbin mechanism stops immediately after needle breaks or thread jams, which places sudden stress on already-degraded plastic gears. If your vintage Singer suddenly developed a Singer sewing machine bobbin not moving problem after a sewing mishap, this is likely the culprit. Unfortunately, replacement gears for these models are increasingly difficult to find as Singer no longer manufactures them.

Bobbin Case Misalignment Fixes

Drop-In Bobbin Systems

Modern Singer machines with drop-in bobbins (featuring a black plastic bobbin area) can appear properly installed while actually being misaligned. The bobbin case must click firmly into position, and the bobbin itself must spin counterclockwise when pulled by the thread.

Quick alignment check:

– Remove and reinstall the bobbin case completely

– Listen for the audible click when seating the case

– Ensure the bobbin rotates freely when pulled by the thread

– Verify the bobbin thread direction follows manufacturer instructions

Removable Metal Bobbin Cases

Older Singer models use removable metal bobbin cases that can warp or become damaged over time. Test your bobbin by removing it from the case—it should spin smoothly between your fingers. Any grinding or catching indicates case damage requiring replacement. Never force a misaligned bobbin case into position, as this can cause further damage to your machine’s timing mechanism.

Bobbin Winder Engagement Check

Verify Sewing Mode

Many electronic Singer models feature a bobbin winding mode that disengages both needle and bobbin movement for sewing. This mechanism can stick partially engaged, preventing normal operation even when you think you’ve switched back to sewing mode.

For electronic models:

1. Check your display for winding mode indicators

2. Push the bobbin winding spindle firmly back to its original position

3. Power cycle the machine completely (unplug for 2-3 minutes)

This simple check resolves the Singer sewing machine bobbin not moving problem in many cases where users accidentally left the machine in winding mode.

Manual Mode Reset

If your Singer has electronic controls, perform a complete reset:

– Power off and unplug the machine completely

– Wait several minutes for capacitor discharge

– Reconnect and restart in sewing mode

– Verify all settings return to default positions

This process clears any electronic glitches that might be preventing proper bobbin movement.

Clean and Lubricate Hook Assembly

Remove Lint and Debris

Accumulated lint can seize the entire hook assembly, creating symptoms identical to gear failure. This is especially common in machines that haven’t been serviced recently.

Cleaning procedure:

1. Remove the needle plate and bobbin case

2. Use a small brush to clean around the hook assembly

3. Remove thread fragments with tweezers

4. Apply one drop of sewing machine oil to the hook race

Regular cleaning prevents 90% of apparent bobbin movement failures that aren’t actually mechanical issues.

Lubrication Points

The hook assembly requires proper lubrication to prevent seizure. Apply sewing machine oil (never household oils) to the hook race every 6 months or 40-50 hours of use. Over-oiling attracts lint and creates more problems than it solves, so use only the recommended amount—typically one drop in the designated oil points.

Cost-Effective Repair Decisions

Singer Stylist 413 Reality Check

This popular vintage model represents a common repair dilemma. Used units sell for $30-50, while professional service costs $100-150. Given the limited availability of replacement plastic gears, most experienced users recommend replacement over repair for machines with this specific Singer sewing machine bobbin not moving failure.

Decision factors:

– Machine value under $100: Usually not worth professional repair

– Plastic gear failure: Typically indicates end of useful life

– Parts availability: Check online sources before committing to repair

Professional Service Guidelines

Only pursue professional repair for:

– Machines with metal internal gears

– Sentimental or high-value models

– Recent purchases under warranty

– Simple mechanical issues (not gear replacement)

For most vintage Singer owners facing a bobbin movement failure, purchasing a replacement machine often makes more financial sense than repairing the original.

Prevent Future Failures

Regular Maintenance Schedule

Prevent 90% of bobbin issues with consistent maintenance:

– Clean the bobbin area after every 8-10 hours of sewing

– Replace needles every 8-10 hours or when problems appear

– Oil the hook race every 6 months with proper sewing machine oil

This simple routine extends your machine’s life significantly and prevents many common bobbin movement issues.

Needle Maintenance Impact

Bent or damaged needles place extra stress on the bobbin drive system. Always use the correct needle type for your fabric, and replace immediately after any impact or thread breakage. A single bent needle can cause enough stress to break aging plastic gears in vintage machines.

Model Identification and Parts

Verify Your Singer Model

Check the model number on your machine’s base or front panel before ordering parts. Singer produced dozens of similar-looking models with completely different internal mechanisms. Cross-reference your serial number through Singer’s online database for exact specifications to ensure you get the right replacement parts.

Parts Availability Reality

Many vintage Singer parts, particularly plastic gears for 1970s-1980s models, are no longer manufactured. Check eBay and specialty vintage parts suppliers, but expect limited availability and premium pricing for discontinued components. When searching for parts to fix your Singer sewing machine bobbin not moving problem, be prepared for potential dead ends with certain vintage models.

Key Takeaway: Most Singer sewing machine bobbin movement failures in vintage models indicate broken plastic drive gears requiring expensive professional repair. Before assuming the worst, verify the bobbin winder isn’t engaged and clean the hook assembly thoroughly. For machines under $100 replacement value, consider upgrading rather than repairing. Consistent maintenance prevents most bobbin movement issues—clean your bobbin area after every 8-10 hours of sewing and replace needles regularly to protect your machine’s delicate drive system.